8 Game-Changing Innovations That Came From Chrysler

We're lucky to have an automotively astute audience here at Jalopnik, and we'd like to think our readers are among the most knowledgeable when it comes to car history and industry minutiae. So we're going to start with a two-part trivia question, and please know that we realize this isn't the kind of thing most people keep top of mind. No cheating allowed. Here it is: Is Chrysler currently a company, and do they still sell cars?

See? We told you it was a tough one.

For anyone who doesn't want to risk inviting targeted minivan ads into their browsing experience by checking themselves, we'll clear it up. Chrysler does, in fact, still exist. The Chrysler.com domain remains paid up and operational, and the brand has a 2026 vehicle lineup that you could write on your hand with room to spare. That lineup consists of the Pacifica and the Voyager.

(The Chrysler 300, for the record, is gone.)

At this point, it can feel like the only innovation on the horizon for Chrysler is the inevitable announcement of a Hellcat Pacifica, something the internet has already decided it wants whether Stellantis does or not. But Chrysler's present-day minimalism hides a much heavier past. For decades, the company repeatedly pushed the industry forward through engineering, packaging, and design decisions that punched well above its weight. That legacy includes ideas that redefined entire vehicle categories, reshaped how cars were built, and quietly became industry standards long after the Chrysler badge faded from the spotlight.

And yes, that "horizon" reference back there was a Chrysler pun. Thanks for catching it. We knew you were paying attention.

The minivan: reinventing family transport

It's easy to forget how strange the modern minivan once seemed, mostly because it worked so well that it rewired expectations almost immediately. Before Chrysler introduced the Dodge Caravan and Plymouth Voyager for the 1984 model year, families with needs that couldn't be met by overloading a sedan had to choose between full-size station wagons or large cargo vans.

Chrysler's breakthrough wasn't inventing the idea of a family hauler, but solving the packaging problem. It was comfy inside thanks to a tall roofline, but easy to get in and out of because it was close to the ground. The sliding doors that you once only saw on the side of a work van now made it easy for your kids to climb in and out, not to mention keeping them from dinging up doors in parking lots (or your garage).

Remember, making the world's first minivan also meant solving all of the engineering challenges that such a thing would entail, including the creation of a front-wheel-drive setup with a transverse engine, crucial if you want to avoid a driveshaft running through the middle of the big empty box that'd ultimately be filled with stuff like three rows of folding seats and a frankly shocking amount of potential cargo capacity. The unrepentant practicality tapped into something special, and a brand new vehicle market emerged, peaking at the turn of the millennium with 1.4 million minivans across all manufacturers sold across the country in 2000. This brought with it billions of miles of suburban efficiency and the occasional existential crisis at the intersections of parenthood, masculinity, and minivans. That's what makes the minivan a genuine Chrysler innovation. It was about rethinking how space was used, and then letting the rest of the industry catch up.

Stow 'n Go: interior packaging reinvented

After Chrysler solved the minivan on behalf of multiple generations of families, it would take just over two decades to solve one of the ancillary problems it created in the process–heavy, unwieldy minivan seats. Readers too young to have at least had a buddy who always had a minivan bench seat chilling against the wall of their garage might not realize that there was a time when not using your seats meant awkwardly wrestling them out of the vehicle and then leaving them somewhere. Chrysler's Stow 'n Go feature, introduced in 2005, changed all that. The system allowed second- and third-row seats to fold completely into the floor, disappearing when not in use and reappearing without tools, planning, or upper-body strength. That meant a minivan could shift from full passenger duty to a flat cargo hauler in seconds. On top of that, the uninitiated might not realize that when you aren't stuffing the seats down into the floor, you can use that area for additional interior storage. (Don't say you never learn anything practical around here.)

What made Stow 'n Go genuinely innovative was the engineering beneath it. Folding seats into the floor meant rethinking the entire underbody, including crash structures, fuel tank placement, exhaust routing, and storage cavities, all while maintaining safety standards and ride quality. It wasn't a bolt-on feature. It was a ground-up packaging rethink that cost about $221 million in R&D, all so that you can disappear your rear seats faster than you can ask yourself where all the good vans have gone.

Torsion-Aire suspension: smarter ride control

By the mid-1950s, most American cars used independent front suspensions with coil springs, while rear leaf springs remained common. In related news, the '50s were not a time when cars were known for a smooth, compliant ride.

Chrysler decided there was room to do better, and in 1957, it rolled out Torsion-Aire, a front suspension system that replaced traditional coil springs with longitudinal torsion bars. This delivered compounding benefits. The design was lighter, more compact, and less expensive. More remarkable than that was the on-road impact of the new approach, though, which included reduced floatiness at speed while also reducing harshness on the road, plus major progress on the driving dynamics we still prize today, like how a vehicle performs when turning or changing speed, plus quality of life improvements like reduced road noise.

Torsion bars never fully displaced coils across the industry, but Chrysler's willingness to rethink something as fundamental as front suspension showed the company's broader approach to engineering: question the defaults, improve what you can, and trust customers to notice the difference when they were behind the wheel. The bottom line here is that if you want to understand how suspension works, Chrysler's Torsion-Aire set a new standard that echoes into today.

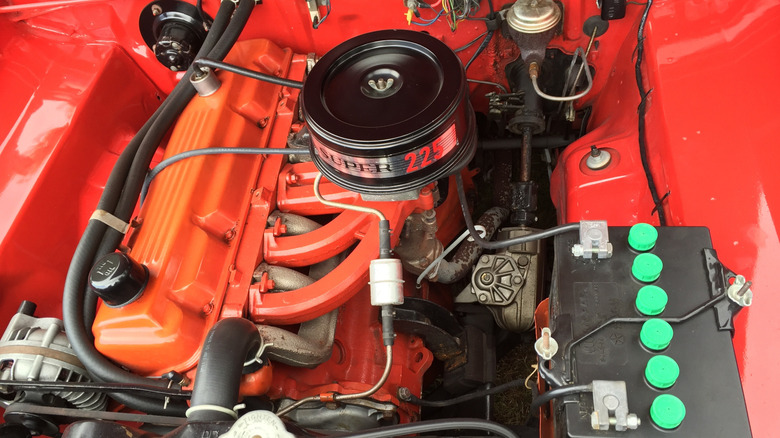

Slant-6: clever packaging meets durability

In the early '60s, the unrepentant automotive excess that resulted in some of the largest production cars ever made was giving way to the first wave of what would later be classified as "compacts," vehicles like the Chevy Corvair and the Ford Falcon. With the smaller footprint came necessary new design restraints, including engines that could deliver power while still fitting under the hood. And so the Chrysler slant-6 was born, an inline six tipped ("slanted") at a 30-degree angle, allowing engineers to lower the hood and windshield without redesigning the entire front of the car. This proof of concept, which debuted as the powerplant for the Valorant, delivered 101 hp and 155 lbs.-ft. of torque at 2,400 rpm.

Among the most significant innovations that would pave the way for the evolution of smaller vehicles, it's also worth noting that over time, Chrysler's Slant-6 refused to die, enduring wave after wave of adaptations to accommodate everything from increasingly stringent emissions requirements to new production methodologies. It did, however, tend to lose a bit of power through each iteration, falling away in favor of diesels and V layouts, first existing United States markets, and eventually disappearing altogether.

TorqueFlite: the standard-setting automatic

As gearheads lament the decline of the manual gearbox, it's tough to imagine a time when the automatic transmission wasn't inevitable. Chrysler entered the game in the '50s with its PowerFlite automatic, but that's not the one that we're talking about today. As that early design gained more traction with customers than expected, the question became whether to run with that success or to continue improving its approach. Chrysler chose the latter, and the result was the TorqueFlite automatic. The TorqueFlite automatic, also known as the A-727, reached production vehicles in 1956, quickly becoming the go-to high-performance automatic and ultimately the standard that helped popularize automatics in general, both inside and outside of the United States.

This was a heavy-duty three-speed automatic, engineered to handle high torque loads at a time when automatic transmissions were still earning their credibility. Its robust internal components, straightforward hydraulic controls, and conservative calibration made it suitable for everything from luxury sedans to performance cars. For a time, it was available in every rear-wheel-drive vehicle that Chrysler sold. At the same time, the TorqueFlite became a favorite in motorsports and high-performance builds precisely because it could be modified to handle even more power without sacrificing longevity. The reputation holds up, even by modern standards, which is why it makes our list of five nearly indestructible transmissions and the cars that use them.

The HEMI: power by design

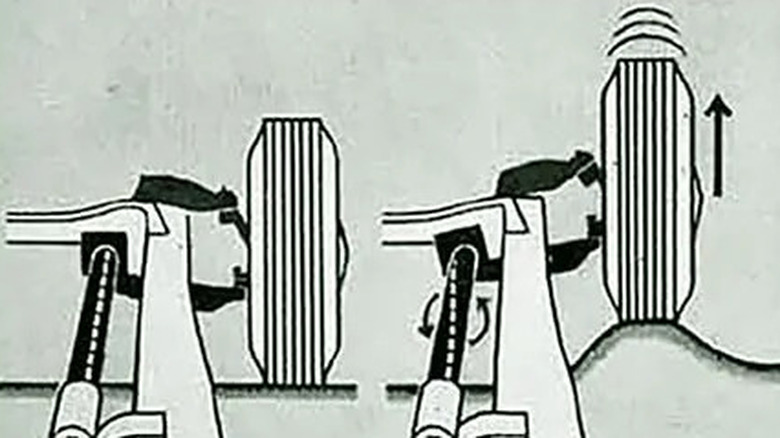

We're going to save you a trip to the comment section right now and start off by pointing out that the history of the first HEMI engine is complicated and that the FirePower V8 that we're talking about right now certainly wasn't the first HEMI, and wasn't even called a HEMI by Chrysler in the first place. There's actually no clear consensus on the first one designed, with historical examples dating as far back as 1905. Regardless of origin, the concept is fairly simple, even if the implications are perhaps greater than you'd expect. The "HEMI" descriptor simply refers to a dome-shaped ("hemispherical") combustion chamber, which it turns out has serious performance advantages, including burning fuel more evenly, optimizing spark plug positioning, and ensuring consistent combustion that generates significantly more force than a traditional design.

While Chrysler didn't invent the concept, it applied it to a V8 engine configuration and normalized its use in mainstream vehicles, with that first cast-iron FirePower motor generating a seriously beefy-for-the-era 180 hp. The long-term influence of the design is difficult to overstate. Variations of hemispherical or near-hemispherical combustion chambers became a reference point for high-performance engine development across the industry, even when manufacturers adopted hybrid or modified shapes to balance cost and emissions. To say nothing of the impact on the industry as a whole, the FirePower V8 deserves a spot on this list if for no other reason than the fact that you can trace a straight line directly from it to the modern Dodge HEMIs for sale today, including the Hellcat 6.2L HEMI V8, which now generates 710 hp and will take a damn Durango from 0 to 60 in 3.5 seconds, if that's a need you have for some reason.

The Airflow: aerodynamics ahead of its time

The Chrysler Airflow is one of those cars that gets remembered as a joke, albeit one that only makes sense to car enthusiasts on the nerdier end of the spectrum. But really, it should be remembered as a turning point. With the dubious honor of appearing on both Time magazine's Most Important Cars list and Time magazine's Worst Cars list, the Airflow was both a commercial misstep and a marvel of early 1930s innovation. After all, we're talking about an extremely early period in automotive history (before Beetles and before Jeeps), when even a concept like aerodynamics was alien and viewed with skepticism. So when early Chrysler began an under-the-radar project aimed at optimizing for airflow, including a cameo from a Wright brother, it was genuinely the beginning of doing automotive aerodynamics somewhat on purpose. Chrysler even had a wind tunnel, though if that's surprising, then it's worth knowing that the technology that makes your car more aerodynamic has been around since the 1800s.

With insights from the tunnel and the brilliance of what passed for aerodynamic engineers at the time, Chrysler came up with a design that included a shallow frame, extremely rigid internal structures, and a body style designed to slice through the air. The result — the Chrysler Airflow — was a commercial disaster, but it planted seeds of engineering and design that would be picked up by the industry in general almost immediately and that still resonate today.

K-Car platform strategy: efficiency at scale

At the edge of insolvency by the end of the 1970s, Chrysler wasn't just in pursuit of a hot new model to save the company or a killer feature to turn the tide. What they really needed was time. The company's solution was not one hero car, but a repeatable way to build many cars: the K-car platform.

The key innovation here wasn't that Chrysler shared parts. Everyone shared parts. What Chrysler did differently was treat the platform as a company-wide survival system: a front-wheel-drive architecture that could be scaled, stretched, trimmed upmarket, and spun into multiple body styles without reengineering the fundamentals each time. From one common source sprung vehicles that were fundamentally similar but remarkably diverse. The platform delivered the Reliant Wagon, but also the Chrysler Limo. Oh, and the Dodge Spirit and the Dodge Caravan, too. The concept saved the company and laid down a foundation that would bring so-called "badge engineering" to every mainstream manufacturer to one extent or another.

And that's the point of ending here. Chrysler's best innovations weren't always about flash. They were often about solving the kind of unsexy, foundational problems that decide whether a car company gets to have a future at all. From aerodynamic experiments to packaging breakthroughs to durable hardware and platform thinking, Chrysler's legacy is bigger than its current two-van lineup might suggest. Three if you count the hybrid. (And they do.)