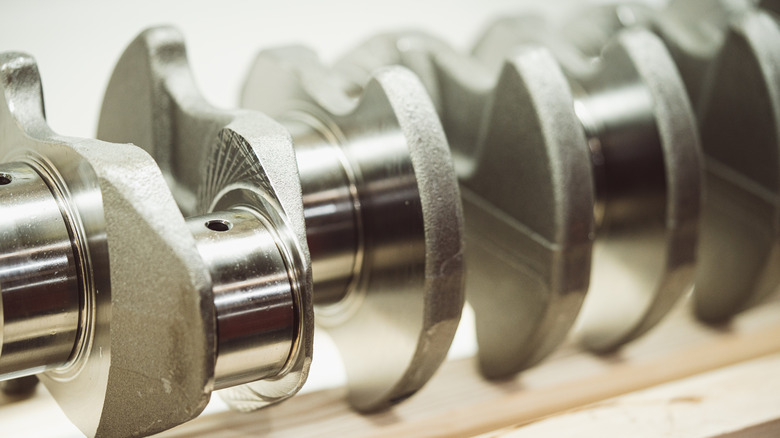

The Difference Between Cast And Forged Cranks – And How To Tell Them Apart

Each modification to a car's engine exposes a new weak point. Maybe it's insufficient injector flow or poor-breathing heads, or it's a crankshaft has the same approximate rigidity as a Twinkie. Whether it's forged or cast can be the difference between "finally hit the nines in the quarter" and "that bang sounded expensive." When you start upping the horsepower on your engine, especially through supercharging or turbocharging, you need to look more at your engine's rotating assembly.

A cast crankshaft is made similarly to a waffle. Instead of batter and a grid-patterned iron, you have molten iron or steel and a complex crankshaft-shaped mold. Once everything's cooled sufficiently, the crankshaft is removed from the mold and final shaping and smoothing can begin.

Forged cranks use an entirely different process that's more like stamping a sculpture out of a bar of clay. First, a massive billet of metal is heated up before being pressed into plain dies to get a shape that sort of resembles a crankshaft. Then, the excess is cut away and a machine twists the metal into a basic crankshaft-like form before pressing it into its finished dimensions. (There's also non-twist forging, which creates fewer internal stresses, though that method requires complex tooling.) Then, it's just a matter of giving the crankshaft a final machining for tolerance.

Why forged is just plain stronger than cast

The difference in strength between these crankshafts comes from their grains. Forged cranks (as well as other parts, such as pistons) benefit from a well-organized grain structure with few (and small) voids, which is why they start as giant rectangular billets; they have a flat grain flow thanks to the hot rolling process. During that process, liquid steel cools into a huge block but is still hot enough to get pressed between rollers, straightening the grains and squeezing out the voids. Forging never fully melts the metal, so it preserves this grain structure. Factory-forged steel crankshafts also have a tensile strength around 110,000 psi alongside exceptional elongation ratings, making them less brittle than cast cranks.

Casting leaves the grains aiming whichever way they please. This is largely due to the formation of dendrites, which are microscopic crystals that push the grains away from each other. The resultant voids weaken the final part. As such, cast iron cranks generally have a tensile strength ceiling of about 80,000 psi. Adding carbon to make nodular (or ductile) iron increases that limit to around 95,000 psi.

Aftermarket cast steel cranks with high carbon content can approach forged strength at about 105,000 psi. If you want the strongest cranks, though, you need to go with forged chromium and/or molybdenum alloys, which can reach 140,000 psi. You can also just carve a crankshaft directly out of a billet, which is excellent for making custom shapes, but it can also weaken the piece since you're cutting through the grains in the metal instead of reshaping or bending them.

Identifying cast vs. forged

You should note that a crankshaft being "cast" doesn't necessarily mean it's made of iron. Ford's flathead V8 was born with a cast-steel crank. Likewise, just because it's "forged" doesn't mean it's steel, though you'll mostly find forged iron cranks in lawnmower engines – or perhaps in a Cummins L10. And just so you know, even though aluminum pistons work fine, it's a terrible metal for cranks.

To spot whether your crank is forged or cast, look for the parting line. On cast cranks, this is where the two halves of the mold came together, manifesting as a thin raised line on unmachined areas. Forged cranks also have parting lines, though they're much wider, which is why they're also called forging pads. Cast cranks also typically have sharp square edges on the counterweights as they retain the exact shape of the mold. Forged cranks, which get stamped and twisted, tend to have rounder and softer edges.

If you have two cranks, grab a hammer and do a tone test, similarly to how guitar builders listen for "tap tones" in pieces of wood to find the most resonant lumber. Cast cranks give a decent "ding" and forged cranks truly ring:

If all else fails, look for the casting number. That will tell you what the material is, as well as the engine displacement, when and where it was made, and even manufacturer-specific information. If you don't know where the crank came from, the casting number will tell you whether it was from a pre-1986 Chevy 350 with a two-piece main seal or a post-1986 350 with a one-piece seal.