How To Know When To Replace And When To Reuse Cylinder Head Bolts

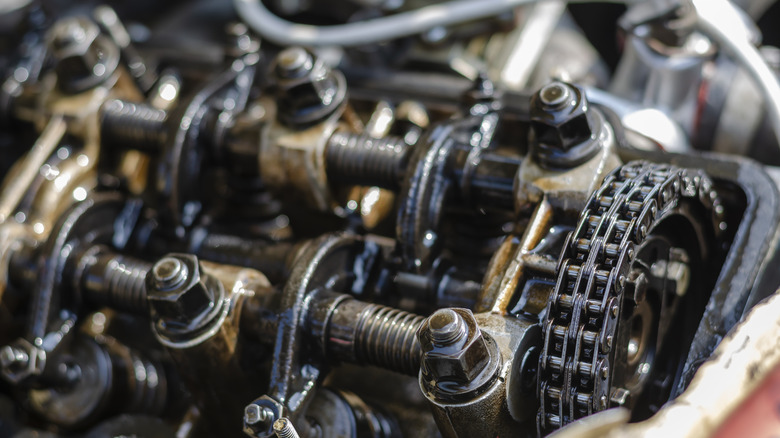

Many don't give a second thought to cylinder head bolts once they're taken out of an engine, thinking of them as just another set of fasteners. But they have a much bigger role, maintaining a consistent clamping force on the head gasket and holding the cylinder head tightly against the engine block. These bolts are engineered to stretch a bit when tightened. This lets them store energy that keeps the joint sealed when the engine is under load. As the engine goes through its paces, a lot of heat and pressure are generated, and the clamping force must be able to withstand that.

To replace or to reuse depends entirely on how much the bolt has stretched. Modern engines mostly use torque-to-yield (TTY) bolts, designed to stretch beyond their elastic limit when installed. While it does help them achieve uniform clamping, stretching a bolt past its elastic range permanently deforms it. You can't expect it to achieve the same clamping force if reused. Standard bolts stretch within their elastic range, meaning the bolt returns to its original shape once removed, much like a spring.

When reusing head bolts may be acceptable

Reusing cylinder head bolts is only worth considering when the engine uses standard, non-TTY fasteners and those bolts pass a careful inspection. The bolt's condition is the first thing you should check. Bolts should be thrown in the trash at the first sign of corrosion, thread damage, galling, or deformation.

Reusing rusted bolts is a particularly bad idea. Threads should be in good condition, too. Many resort to chasing damaged threads, but those are just cosmetic improvements. Removing material like this puts a dent in strength. Another thing you should take a look at is the bolt's length. Bolts that have been stretched too much are longer than their specification and may be obviously distorted. Clamping force takes a hit with even small increases in length, or any other permanent deformation.

If you decide reusing is the way to go, lubricate the bolts lightly with engine oil. This helps in achieving consistent clamping, provided you follow the service manual's instructions. Never skip cleaning the bolts. No residue or debris should be left on the bolts or bolt holes, as that can mess with your torque readings.

When head bolts must be replaced, and why it matters

There are situations where replacement is not optional. Torque-to-yield head bolts should never be reused under any circumstances. A surefire way to find out if the bolts are TTY, and thus single-use, is to consult your service manual, which usually has specific torque-plus-angle tightening sequences for such bolts. They just can't give accurate, reliable clamping the second time around since the initial installation stretches them beyond their elastic limit. Reinstalling them isn't worth the improper sealing and outright bolt failure it risks. You don't want to be stuck trying to remove a broken bolt without breaking it. Replacement is the smarter move, even from a financial standpoint.

With damaged or overstretched bolts, there's no question whatsoever, no matter what type of bolt it is. Under combustion pressure, damaged bolts cannot maintain tension properly, so they let the cylinder head lift microscopically. It doesn't sound like much, but even minor losses in clamping can result in head gasket failure and leakage of coolant or oil. Warping of components and mixing of fluids is also possible in severe cases.

So avoid reusing bolts whenever you can. After all, mistakes like these keep your mechanic rich.