What Causes Engine Knocking (And How Can You Prevent It)

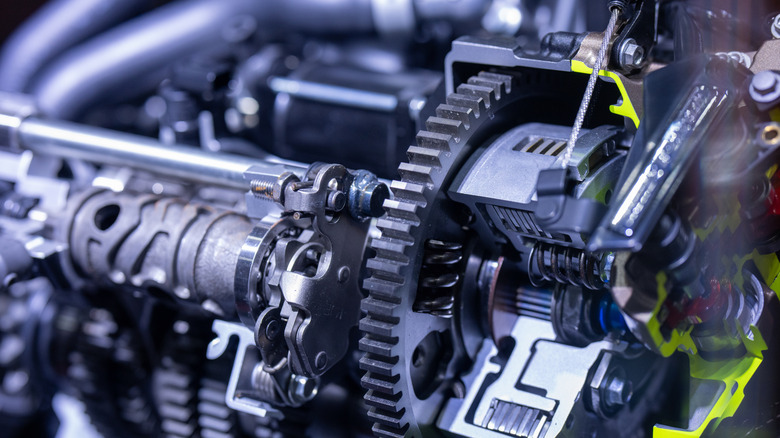

Engine knock is the sharp, metallic sound that cuts through the hum of a healthy engine. At its core, engine knock is a problem of timing. In a knocking engine, parts of the air-fuel mixture don't ignite when — or where — they should. The ignition happens too early or in more than one spot at a time, causing mini-explosions in the cylinder. The irregular motion of the mini-explosions conflicts with the motion of the piston, and this is what causes the knocking sound.

These irregular explosions are more than just loud. They are hard on pistons, connecting rods, bearings, and valves in a way that the engine was never designed to handle. If left alone long enough, the end result can mean warped parts, metal-to-metal contact, damaged cylinders, or even a failed engine.

What's surprising is how even the most normal conditions can trigger this domino effect. This includes a tank of low-octane fuel, spark plugs that are no longer young, carbon buildup from short city driving, or timing that's drifted far enough to spark the spark plug just a little too soon. Plus, knocking never resolves itself. It just gets louder, hotter, and more expensive. However, most instances of knocking start off small. If you catch the problematic areas early, you can prevent knocking from being a problem at all.

The most common triggers behind a knocking engine

Contrary to how serious it can be, most instances of engine knocking are the result of a few common problems occurring within the combustion cycle. One of the most common causes is simply using a type of fuel with an octane rating that's lower than what the engine is designed for. Low-octane fuel does not resist ignition as much, which means it will often ignite prematurely when it is under too much pressure.

Engine knocking is also one of the symptoms of worn-out or malfunctioning spark plugs. If a spark plug is misfiring, igniting late, or unable to sustain a steady spark, the ignition process will not start as it should, allowing random self-ignition to occur within the cylinder. This is why spark plugs are often first in line in many maintenance schedules, and why the symptoms of poor idling or acceleration are often seen alongside the initial symptoms of knock. Meanwhile, carbon buildup is a slower, stealthier process that occurs over time thanks to poor fuel or combustion issues. Eventually, this buildup reduces the size of the combustion chamber and raises the compression ratio, making early detonation very likely.

In more mature engines, additional factors can come into play, such as a fouled injector, a weak fuel pump, or stretched rubber belts. These causes all upset the delicate timing of when and how the mixture ignites, transforming a smooth process into the random mini-explosions that characterize engine knock.

How mechanics track down the root of the problem

Once the knocking is regular enough to be noticed, the process of determining the cause is a matter of listening and experimenting. In today's engines, the first part of the process is made easier: the knock sensor will typically activate a vibration warning to the engine control module, and if the timing adjustments can't even out combustion, the check engine light will come on. This won't reveal the cause on its own, but it will let a technician know that something is amiss in the combustion cycle.

The next step is systematic. Spark plugs are the first place to look, and their gap, condition, and firing order will tell a great deal about how well each cylinder is firing. Oil level and quality are next, as lubrication issues can hasten its effects if knock is already present. Fuel quality is also an early diagnostic point; sometimes all it takes to cure knocking is to drain the tank containing the low-octane or dirty fuel. After all of that, check your timing either by scanning the ECU or looking at physical components such as belts, chains, or sensors.

When knocking points to deeper mechanical stress

If basic checks don't calm the knocking, the process of diagnosis moves towards the internal health of the engine. A compression test may reveal worn piston rings or carbon buildup that might be causing the cylinder pressure to increase above what the engine can handle. Injectors and pumps should also be tested for uneven delivery of fuel.

At this point, it's wise to also try and determine how the engine has been trying to protect itself. The engine has probably been compensating for the problem by adjusting the timing or fuel delivery in order to quiet the knock. Only then are mechanical issues like bearings or loose tolerances considered, not because they are uncommon, but because they are the worst possible case of engine knocking. This is pretty much the end of the knocking issue spectrum, and at that point, the sound is a sign that the engine has been pushed for far too long.

How to prevent engine knocking before it starts

An easy way to prevent knocking is to simply use higher-octane fuel. Engines that require it will sit quietly while you're using the wrong fuel, but the stress causes problems well before the first knock is heard. Even if your car has low-octane fuel, it's okay to top it up with something that has a higher number (just like how it's permissible to mix 87 and 91 octane). Regular maintenance is also very helpful. Using fresh oil ensures that temperatures are well regulated and that the moving parts are well cushioned, making it less likely for hot spots or friction-induced detonation to occur.

Checking spark plugs often makes it easy for you to spot any issues early, and replacing them in a timely manner helps to prevent misfiring or timing issues. Even without the knocking sound, as a rule of thumb, you should change your spark plugs after every 80,000-100,000 miles of driving.

You should also be wary of carbon deposits building up gradually on valves and piston tops, particularly on vehicles driven under heavy city traffic conditions. An occasional long road trip, good fuel additives, or additional cleaning during maintenance will help maintain normal compression and avoid the "extra squeeze" that promotes early ignition. Together, these small practices are especially useful in keeping the combustion cycle predictable, the engine smooth, and repairs far from sight.