Why Did Corvettes Switch From Fiberglass To SMC Body Materials?

If there's one factoid the average person knows about Corvettes, it's that those muscular molded panels are made of fiberglass. Well, they were, anyway. That factoid was only true up until around the era where General Motors stopped using whale oil in its automatic transmission fluid. In 1973-ish, Chevrolet switched the Corvette's body panels to a material called SMC, which stands for "sheet molded compound," "sheet molding compound," or "sheet molded composite," depending on how much you want to cover your bases.

The timeline of the plastic fantastic's move away from glass reinforced plastic (GRP), which isn't just a synonym for fiberglass but one type of fiberglass, is a little complicated, so we'll address that later. Before discussing the "when," we must discuss the "why," which is a lot easier to explain. GRP is a reasonably light, strong material that works beautifully in boats and airplanes as well as Corvettes, but if GM can find a superior material for its cars, it will. As long as that material is cheaper and easier to work with, anyway.

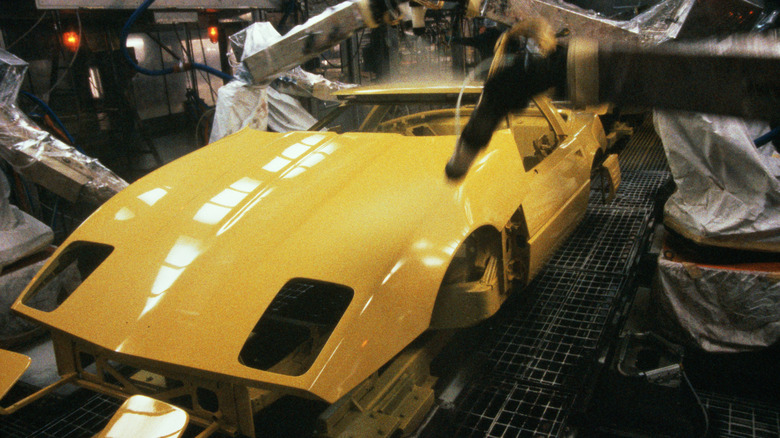

SMC is pretty miraculous compared to GRP. Though these materials are reasonably similar, with GRP using thin glass mats embedded in resin and SMC using chopped glass fibers strewn throughout resin, SMC is far less laborious and faster to make. And SMC can be injection molded, requiring less human labor, resulting in more consistent quality. Even better, SMC is more impact-resistant and has a superior strength-to-weight ratio. Plus, SMC is usually smoother and more uniform in appearance than fiberglass. There are literally no downsides to switching from GRP to SMC, so GM happily did just that.

GRP to SMC is A-OK

Corvette body panels completely transitioned from fiberglass to smoother, stronger, lighter SMC by 1973. The thing is, it didn't happen all at once, as individual pieces became SMC after GM moved to the press-mold panel process in 1968. In 1970, the instrument panel supports became SMC. By 1971, SMC took over the rear quarter and end panels. In 1984, C4s got one-piece lift-off SMC roof panels to replace the T-tops, and in 1993, some inner panels started using recycled SMC.

A transitional material called "Genite" was apparently also used. "Genite was a proprietary material created by the General Tire and Rubber Company and people posting in Corvette forums note that it was used for Corvette doors in late 1969, as well as some rear quarter panels in 1970. Genite panels are described in the forums as being light gray vs. the dark gray or black of earlier fiberglass panels. SMC panels are apparently also light gray, though SMC is noted to have a slight marbling effect not seen in Genite.

Corvettes still rely on sheet-molded compound as the primary composite for their body panels, but other materials have been added over the years. In 2004, Le Mans Edition C5 Corvettes received a carbon fiber hood. In 2006, C6 Z06s got carbon fiber fenders, floorboards, and wheel liners, while C6 ZR1s received carbon fiber hoods and splitters. For the 2014 C7 generation, all 'Vettes got carbon fiber hoods and removable roofs.

Thou shalt not steel, Corvette

Corvettes weren't supposed to have fiberglass bodies. The original plan was to use steel stamped out on Kirksite dies. But to get that spiffy new Corvette finished in time for the January 1953 Motorama show, Chevrolet had to turn to GRP, which could be churned out way faster.

At first, the Corvette's fiberglass panels were made by laying hand-cut glass mats into phenolic or wood molds, coating the mats in resin, and pressing any bubble out with a roller or paint scraper. This might have been fine for a one-time-use concept car destined for the crusher, and even for a limited production hand-made car, but certainly not for something mass produced. Eventually, Chevy contracted out to suppliers who were experienced in making fiberglass panels with the vacuum-bag method, which is both quicker and more consistent.

Abandoning steel turned out to be a big-brained move long-term, as fiberglass is lighter and easier to make in weird, flowy shapes. It never rusts, either. It was even stiff enough to use for the C4-C7 Corvette transverse leaf springs, aka "monoleafs." (Or is it monoleaves?)

All this said, the Corvette did drop the ball in one area. GM design honcho Harley Earl was inspired to use GRP for the Corvette after seeing the Glasspar fiberglass-shod Naugatuck Chemical Alembic I sports car. That car used a property of fiberglass to its advantage for publicity: Translucence. During a photo shoot in Life magazine in the fall of 1951, the unpainted car's body was lit from underneath, causing it to glow, which you can see documented in this Hagerty piece. Where are our glowing Corvettes, GM? We could have had them this whole time!