Piston Ring Endgaps Matter More Than You Think: Here's Why

Regulating heat and pressure inside an engine is necessary for its healthy operation. Piston ring end gaps play a vital role in that, but they can be easily overlooked as a minor measurement. In reality, though, these gaps are intentionally placed where they are to compensate for thermal expansion and pressure balance. As the piston and cylinder heat up, each component expands at a different rate. The top compression ring sees the most heat from temperature increases, thus growing the most. The end gap exists to give that growth somewhere to go.

But that gap needs to be just right, or it will cause problems of its own. If it's too tight, the ends of the ring will bump into each other when the engine heats up. The ring doesn't have space to expand inward at that point, so it grows outwards, making it push harder against the cylinder wall. A gap that's too wide creates a different problem. Excessive clearance can result in loss of compression, reducing power and possibly compromising oil control. So, yes, having proper piston ring gaps are more important than people realize — unless you have a combustion engine powering your vehicle that doesn't need oil at all, which would let you make do without piston rings altogether.

Gap size depends on bore, heat, and application

How much end gap is required is determined by the size of the bore (which, along with the stroke, determines your engine's power). That is why some specifications require the end gap to be calculated using both ring dimensions and bore size instead of being treated as a fixed number. Heat load is the other major variable. Engines running forced induction or high compression generate far more heat and cylinder pressure. To stop the rings from colliding under peak load, these engines require a larger gap.

In many performance builds, the second ring is gapped slightly larger than the top ring to prevent pressure from becoming trapped between the rings. That pressure, if not relieved, can lift the top ring off the piston and reduce sealing. The goal across all applications is the same, which is to maintain control of heat and pressure so the rings can seal without destroying themselves. Worn rings are one of the most common causes for misfiring cylinders.

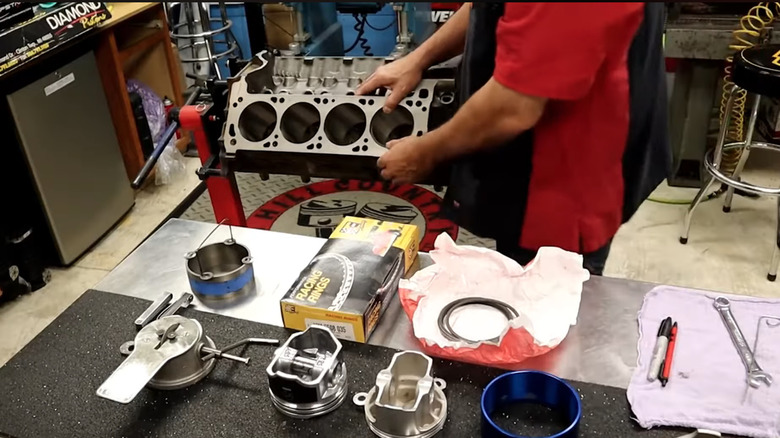

Installation, orientation, and the cost of getting it wrong

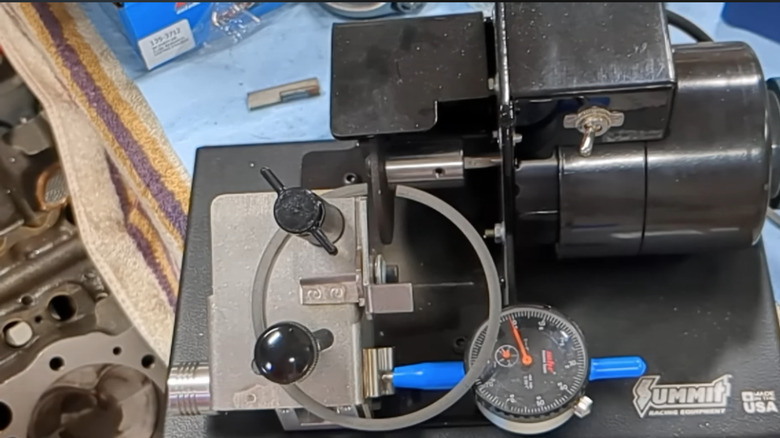

Improper installation of the rings can ruin even the most precisely-sized gaps. The ring must be perfectly positioned square in the bore; a squaring tool is usually used to ensure this is the case, and afterwards, the gap can be measured by using a feeler gauge. If the rings need to be filed, it should be done meticulously so as to avoid making mistakes. If that happens, you'll need to start over with a new ring.

Once installed on the piston, ring orientation matters. End gaps should be spaced apart around the piston to avoid creating a direct path for blow-by. While rings are designed to rotate during operation, proper initial clocking minimizes oil contamination and sealing issues. The consequences of mistakes are well documented. Rings with gaps that are too small can destroy pistons and cylinders in short order, and rings that are too loose reduce compression, increase blow-by, shorten oil life, and hurt performance.