The Difference Between Variable Valve Timing (VVT) And Variable Valve Lift (VVL), Plus How They Work

Variable valve timing (VVT) and variable valve lift (VVL) have very similar names, both referring to variable valve performance. Does that mean that they are basically the same thing? The are most definitely not the same thing. They are both designed to achieve the same results, a more efficient engine that uses less fuel and gives off fewer emissions. But the way they each goes about it is different.

Variable valve timing is just what it sounds like. It controls the timing of when the valves open or close. That's an important job, since the more power the car needs, the earlier the intake valve should be open and the later the exhaust valve should close. The opposite is true then the engine idles. In comparison, variable valve lift has nothing to do with when the valves open or close, but it does control how much the valves open and how long they stay open. The higher the rpm, the higher the valves should be open and the longer they should stay open.

All of this is done to control when and how much air and fuel go through the cylinders. When that happens, the pistons and other parts don't work as hard, meaning the engine uses less fuel. That helps your car's gas mileage and makes it a little friendlier to the environment.

How VVT works

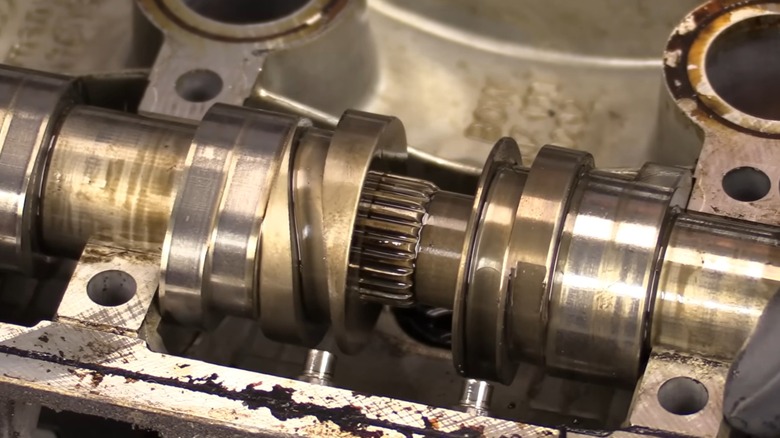

So, naturally, a piston that is moving up will push air up and out of an open valve. A piston on the way down is going to pull air down with it. VVT is all about regulating airflow to control temperature, power, and efficiency. At higher speeds, the intake valves will open early and close late to provide more air flow, and, thus, more power. The reverse happens when the engine is idling, because less power is needed. It's "variable" because piston speed will change along with the rpm.

VVT can either work by utilizing set targets that are mechanically triggered by rpm changes, or, in the case of continuously variable valve timing (CVVT), it is regulated electronically, allowing for a little more responsiveness and versatility. VVT can be used on both the intake and exhaust camshafts, but some engines only utilize it on one side, normally the intake. Certain Audi engines, for example, use it only on the intake.

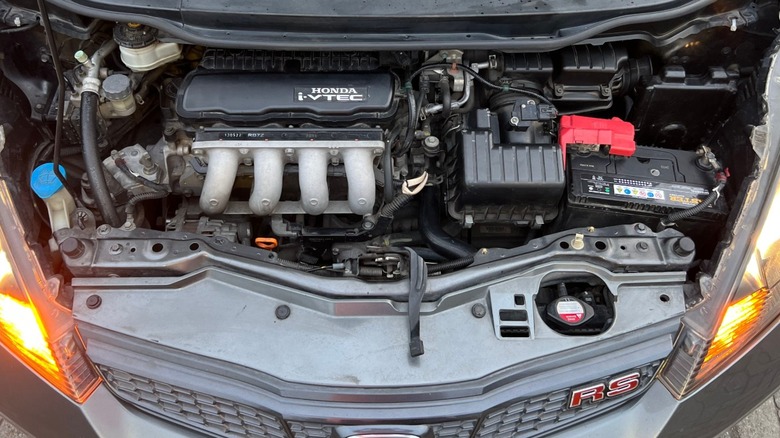

VVT is nothing new. Patent applications for VVT systems go back to 1880. The first vehicle to use a variable valve mechanism was the 1903 Cadillac Runabout. It didn't really catch on, though, until it was put into the Alfa Romeo Spider 2000 nearly 80 years later. Other companies took the technology and ran with it, some even advancing it. You've likely heard of Honda's VTEC system. This system combines control of both valve timing and lift (we explore the specifics of VTEC maintenance here).

The benefits of VVT

We're all for anything that causes us to visit the gas pump less often. VVT not only improves gas mileage but reduces emissions. It accomplishes this by helping the engine to run more efficiently, thereby burning less fuel. That's the result of matching airflow with power needs in real time and controlling the air fuel mixture. One study concluded that the use of VVT has the potential to increase fuel efficiency by 15%. For now, real world numbers are a little lower than that, but still significant. In the 2014, Canada's Ministry of Natural Resources found that the use of VVT reduces emissions and fuel consumption by 1% to 6%.

But VVT can also improve your car's performance and handling. It does this by optimizing torque, which, in turn, creates smoother acceleration. But this is also another reason to make sure you change your oil regularly at the intervals recommended by your car's manufacturer. A VVT system needs good oil flow to work properly. The oil needs to be clean and of the right viscosity to keep the parts from wearing prematurely. Once the VVT system is impacted, your engine's overall performance will decline.

It's no wonder that almost every modern gas-driven vehicle employs VVT. Of course, the major automakers have their own versions of it. Ford uses twin independent variable camshaft timing, and GM's version is dual continuous variable cam phasing. Nissan, Hyundai, Kia, and Volvo all use some form of continuous valve timing.

How VVL works

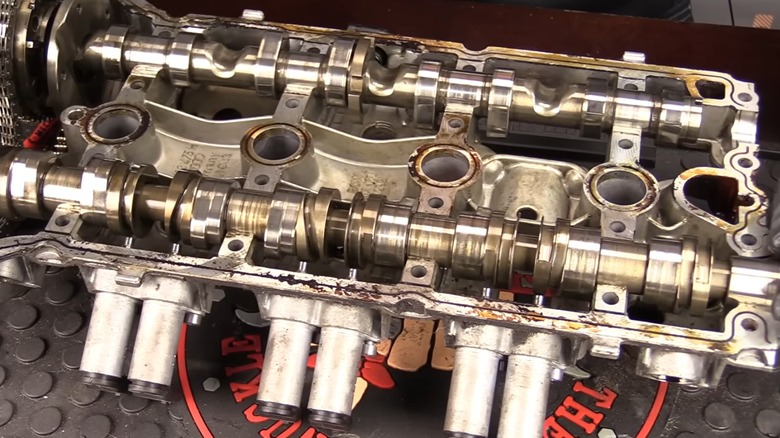

So, while VVT controls when valves open and close, VVL controls how high and for how long the valves open. This is another way of regulating how much air flows through the cylinder. The faster the engine needs to go, or the higher the rpm, the higher and longer the valves open. Slower speeds or lower RPM, on the other hand, don't require as much air flow, so the valves don't open as long or as much. In other words, VVL varies the height and duration of lift with changes in rpm. By the way, you may be interested in our guide on upgrading rocker arms, another important part that impacts valve lift.

Normally, VVL will switch between two or more set profiles. During idling and at lower rpm, the VVL will operate at the lower lift lobe, where it will stay most of the time. It will switch to the higher lift lobe during acceleration and at higher speeds. This two-lobe system is a called discreet variable valve lift (DVVL). Other systems, known as CVVL, allow for continuously varying the valve lift. Not all engines with VVL use it on both the intake and exhaust. Certain turbocharged Audi engines, for example, just use it on the exhaust side.

Different automakers have their own spin on this technology. Discreet systems include Honda's i-VTEC, Chevy's Intake Valve Lift Control, Mercedes' Camtronic, and the Audi Valvelift System. CVVL systems include BMW's Valvetronic, Fiat's Multiair system, and Toyota's Valvematic.

The benefits of VVL

The benefits of VVL to engine performance are pretty much the same as VVT, except those benefits are achieved in different ways. For example, instead of opening a valve early or closing it late as the car reaches higher rpm, VVL will switch to a higher lobe, which will keep the valve open longer and make the opening bigger, allowing for more air and fuel to flow through the cylinder. As it does this, VVL is complementing the car's VVT system.

One way very smart people measure the efficiency of an engine is to calculate its brake specific fuel consumption, or BSFC for short. In very simple terms (the only kind we understand), we calculate BSFC by dividing the fuel mass flow rate by the engine output power. So, basically, it's how much power is being produced for the amount of fuel that's used. A 2023 study by Zhou et al. and shared by Science Direct, with the catchy title, "Effects of different valve lift adjustment strategies on stoichiometric combustion and lean burn of engine fueled with methanol/gasoline blending," found that use of VVL at partial load conditions can improve BSFC by 10% to 14%. Not too shabby!

One of the drawbacks of VVL is that it is expensive to manufacture. That means it's not as widely available as VVT. You'll generally find it in higher-end luxury vehicles, though not exclusively. Toyota, as an exception, employs it across much of its product line.

VVL and VVT often work together

The best valve optimization comes when VVL and VVT team up to get the most efficiency out of an engine. That study we mentioned earlier that found that VVL can increase engine efficiency (specifically the BSFC) by 10% to 14% also found that when an engine was equipped with both VVL and VVT, there can be a 15% to 20% improvement at low to medium speeds. They are truly complimentary systems — VVT controls how soon or how late valves open and close, while VVL controls how high and how long they open.

There are several car companies that use both VVT and VVL systems on some of their models. Honda's i-VTEC system, for example, combines both VVT and VVL. The Audi Valvelift System uses VVT on the intake valves and VVL on the exhaust cam. Toyota puts its Dual VVT-i system on both the intake cam and exhaust cam of its engines, as well as its Valvematic VVL system on the intake valves.

In short, VVT and VVL are separate systems that work toward the same goal -– optimizing your engine's efficiency. They both work to regulate air and fuel flow in the cylinders to control performance and temperature. This results in the engine using less fuel, which means lower emissions and less frequent trips to the gas pump. If you'd like to learn more, check out this deep dive about how VVT works.