Why Strokers Make Their Power And Torque Down Low

As Billy Squier once so aptly put it, "if you're in the game, then the stroke's the word." Of course, those words might not have been about cars in particular, but stroking your engine is indeed a great way to raise the stakes in competitions for better performance. Stroke is basically a measure of how far a piston moves in a cylinder. To get that measure, you take the position of the crankshaft when the piston is at its highest point in the cylinder and compare it to where it is when the piston is at its lowest.

Similarly to boring a cylinder — which increases its diameter – stroking adds displacement to the engine by lengthening how far the piston moves. With more displacement, you can get more of the fuel/air mixture into each cylinder. That's why we say that stroke and bore are the two specs that decide an engine's power. There are some obvious limits, though, as there's only a certain amount of vertical room in the engine block.

Regardless, stroking has definite advantages over forced induction to help engines deliver more muscle right off the bat. Instead of waiting for a turbocharger to spool up, for instance, the longer stroke starts affecting engine operation as soon as the pistons start moving. This is why stroker engines are more powerful at lower rpm.

The physics behind low-end stroker power

The thing is, stroking doesn't so much change the length of the cylinder itself; it increases the length of the crank pin moving the pistons up and down. Basically, the piston head is attached to a connecting rod that attaches to the crankshaft via an offset crank pin. When combustion pushes the piston down the cylinder, it pushes on the crank pin, which acts like a lever to move the crankshaft. (Crank pins are key to the differences between cross-plane and flat-plane cranks, too.)

Stroking typically means increasing the offset distance of the crank pin, which puts more space between where the piston meets the pin and the centerline of the crankshaft. Lengthening the crank pin is like making the input arm of a lever longer, delivering a noticeable force advantage. Stroked engines effectively combine the greater force from the longer combustion event with a longer input arm of the lever. Because of how instant this power increase is, some experts say that a stroked engine turning at lower rpm is doing the same job as a similar non-stroked motor that's running a few thousand rpm higher. There's no such thing as a free lunch, though, and the stroker-engine power feast can come with a pretty high price.

Pros and cons of stroker engines

The unique performance profile of stroker engines rewards gearheads with increased horsepower and torque almost as soon as they touch the gas pedal. It's helpful on the drag strip for jumping off the line, on the trail for climbing over rocks, and even just in regular everyday traffic where your engine is usually kept at a relatively low rpm.

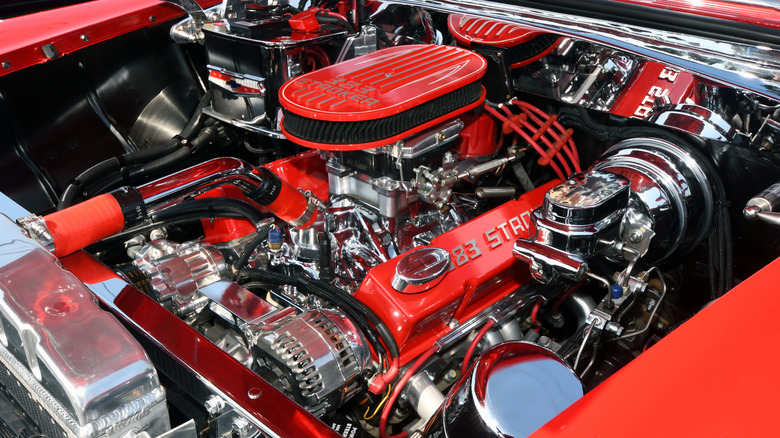

But there's no getting away from the fact that the actual process of stroking an engine can take plenty of time, money, special tools, and expertise. Unlike bolting on a supercharger or turbocharger, you have to get deep inside the engine block to stroke an engine. A typical setup requires you to completely remove the block itself and replace the crankshaft, pistons, connecting rods, and bearings. In certain cases, you also may have to grind down areas of the block to accommodate the longer distance the piston travels, which can put you at risk of damaging the system of coolant channels that helps to prevent overheating. Cause damage there, and you're facing yet another cascade of potentially expensive engine work.

Many parts of a stroker kit are likely to be more expensive than stock components, too, since they have to be engineered to handle the extra forces being produced. Those forces are also why some high-performance cars need forged pistons even in stock applications.