The Difference Between LS And Vortec Engines (And Why Fans Love Them)

There's a reason why gearheads put both LS (not to be confused with LT) and Vortec engines under the same umbrella of "LS", despite GM originally assigning them different badges. (And in case you're wondering, here's a full rundown of what "Vortec" actually means.) Both are members of the same Gen III and Gen IV small-block family, after all. The interchangeability of parts across the platform is also very strong thanks to their shared DNA and core architecture. Design wise, their similarities are seen in a single-cam pushrod valve train, six-bolt main bearing caps, and a deep-skirt block design. Another thing they both have is coil-near-plug ignition, and even the bore spacing is the same across the board to keep the overall size compact.

Where the LS and Vortec engines differ is application. Trucks and SUVs were the primary use cases for the Vortec engines, while LS labeled engines were designed for performance cars. The latter used aluminum blocks for weight reduction, and higher factory output was ensured by using intake manifolds and accessory drives designed specifically for the car it was to be installed in. The Corvette, Camaro, and GTO all received these engines.

Where the differences actually matter

Both the LS and Vortec engines use different materials for their engine blocks. Due to the sustained loads and cylinder pressure in trucks, Vortec engines commonly use cast iron blocks. These had thicker cylinder walls that could tolerate extreme conditions, but they were also heavy. The popular 4.8, 5.3, and 6.0-liter versions of the engine all used cast iron. On the other hand, LS engines went for aluminum blocks for a lighter weight and improved performance.

Depending on the year and displacement, the design of cylinder heads may be the same for both engines. Cathedral and rectangular port heads are present in both families, and they can be mostly interchanged between the two.

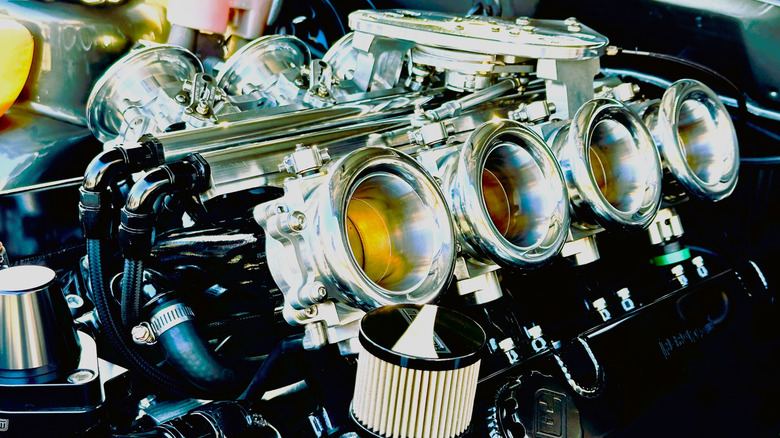

Early LS engines like the LS1 used flat-top pistons and a relatively high compression ratio of 10.2:1 to support strong performance. Stronger variants like the LS6 and LS7 pushed compression further with improved piston and combustion chamber designs. In contrast, Vortec truck engines typically used dished pistons and lower compression ratios in the 9.4:1 to 9.5:1 range, prioritizing towing capability and boost tolerance. Performance was given a bump for the engines in their fourth-gen applications, and features like drive-by-wire throttles, variable valve timing, and active fuel management were made available.

Why enthusiasts love both

Two things made the LS and Vortec fan favorites: flexibility and affordability. Performance builds opted for the LS as their engine of choice, taking advantage of its aluminum construction and efficient cylinder heads. What made it particularly famous, however, was how compact it managed to be. It was small enough to fit in places once occupied by small-blocks while delivering big horsepower. When not bound by cost and emissions controls, the platform was capable of so much more, as demonstrated by factory variants like the LS7 and LSA.

Vortec engines had a different claim to fame. Because they were churned out in big numbers for trucks and SUVs, they were everywhere. This, coupled with the low cost of entry and the fact that parts were abundant, made the Vortec easy to swap in. It was compatible with many of the same upgrades as the LS, from cylinder heads to intake systems, thanks to their shared basic architecture. Builders had peace of mind when adding turbochargers or superchargers, because they knew the iron blocks and thick cylinder walls could take whatever was thrown at them. But if you ever get bored with LS swaps, here are some alternatives you can try your hand at.