Cylinder Honing Vs Boring: The Difference And Why It Matters

The bore of a cylinder (along with the stroke and the number of cylinders in the engine) is what determines displacement. Increasing the bore can help boost the horsepower of your engine, which is what some engines are modified or rebuilt for. That's also why both boring and honing are important parts of many engine rebuilds or modifications. Boring is a machining process that is used to remove material from the inside of a cylinder and increase its diameter, while honing is used to provide a proper finished surface after the boring process is complete. Boring can also be used to refresh old and worn cylinders.

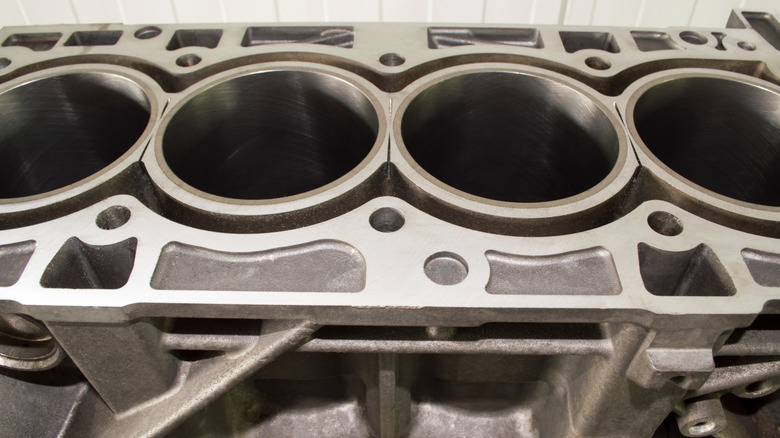

Engine cylinders are prone to distortion, due to the heat and friction that come with engine operation. They can get tapered or develop surface damage on the inside that piston rings are not designed to accommodate. Now, unless you install cylinder sleeves to freshen up your engine block, the worn or misaligned bore needs to be cut back to a true, straight axis. However, this will increase the bore of the cylinder, which means you will have to use slightly enlarged pistons, as the original ones won't fit properly.

The material is removed in a very deliberate and measurable way using a single cutting edge. The requirement is to eliminate all distortions and properly align the block with the crankshaft. While boring does that job, it also leaves tool marks and fractured metal on the surface. Such a rough surface is not suitable for piston rings. But finishing was never the goal. That's taken care of by honing.

Honing refines the cylinder walls and allows the pistons to seal properly

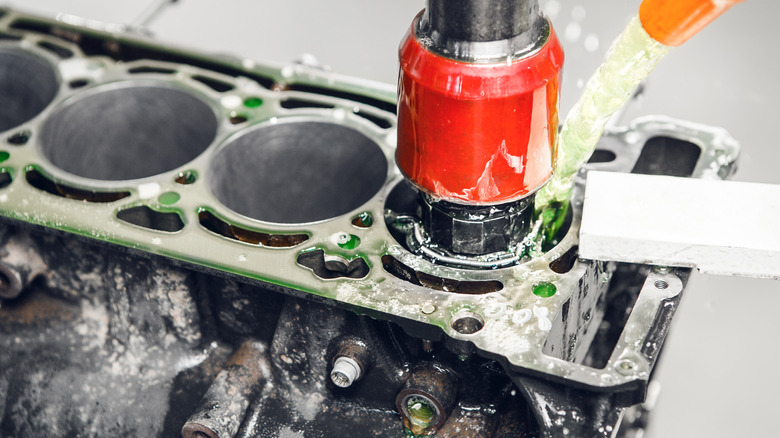

Honing is used to provide the finishing flourish to a cylinder bore. Using abrasives mounted on an expanding mandrel, honing creates a consistent texture on the surface. The smooth texture is produced as the abrasive moves up and down and contacts the bore evenly, spreading the cutting forces.

Honing leaves a specific cross-hatch pattern all over the cylinder surface, which consists of controlled valleys and smooth plateaus. These are deliberate imperfections on the surface of the bore that help retain oil and support the piston rings, which need a consistent surface texture for quick seating and friction-free operation. That's why proper crosshatching can make or break an engine. Another advantage is that honing removes the rough and worn out metal on the surface and exposes more stable material inside.

Honing is directly responsible for determining oil consumption, blow by, wear rates, and engine efficiency. The final dimensions of the bore are achieved in this stage. The pressure and abrasive need to be just right, and the surface needs to be lubricated properly. Given the tight tolerances of this process, the machine must be rock solid and stable.

Why the difference matters in real engines

Do not confuse boring and honing as the same thing, as it could lead you to some very expensive mistakes. As each process solves one specific problem, replacing one with the other can lead to compromised results. Boring fixes the size and alignment but cannot give a finished surface against which the rings can provide adequate sealing. Honing gives a perfect finish and geometry but cannot be used to correct major distortion, although it may be able to fix minor cylinder wall scoring issues.

Order also matters for this combination to work perfectly. Remember, boring always comes first to establish the correct geometry, and honing comes second to give you that beautiful finish and bring the bore to the exact size. If you skip any one of these processes, there will be consequences. Skipping honing means your engine will be left with fractured metal pieces that will eventually accelerate wear. Skipping boring and trying to hone away a major distortion will waste time and risk uneven cylinders.