What Are The Four Strokes Of An Engine?

Almost all gasoline engines, whether they're efficient-yet-less-refined four-cylinders, high-horsepower V6s, or growly and torque-rich V8s, use much the same process to create power. The "Otto cycle" engine, named after German engineer Nikolaus Otto, who built the first practical four-stroke combustion engine in 1876, became the first viable, compact alternative to the steam engine. It was the first to operate and create power using intake, compression, power, and exhaust strokes (hence the name four-stroke) despite the invention being patented by French engineer Alphonse Beau de Rochas in 1862.

The rest, as they say, is history, but there's a catch. Nikolaus Otto's patent was eventually revoked in 1886 in favor of Beau de Rochas' earlier invention. Even so, the four-stroke engine became more synonymous with the Otto cycle, partly because the German was the first to build a working prototype. The Otto-cycle engine became an overnight sensation owing to its efficiency, reliability, and relatively quiet operation, and it's still widely utilized today for cars, trucks, motorcycles, and small machinery.

The intake stroke kickstarts the combustion process

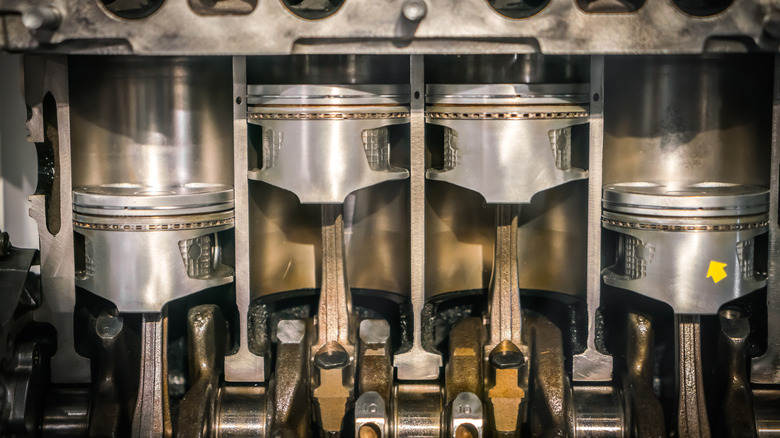

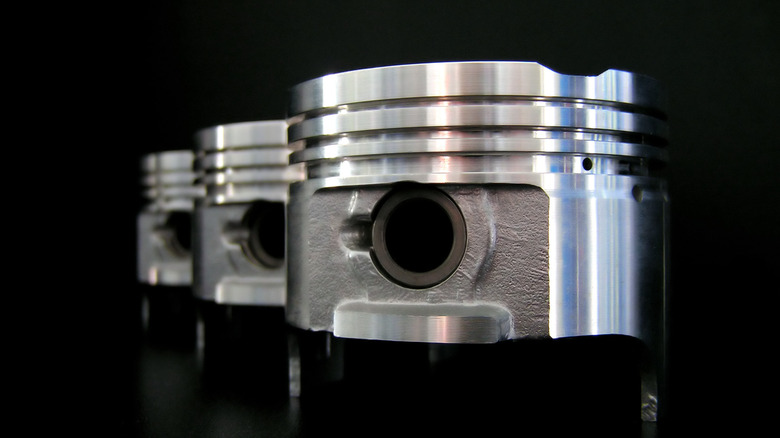

The four-stroke Otto cycle (or, more officially, the Beau de Rochas cycle) refers to the four strokes of a piston. In a single "cycle," the piston has to travel up and down the cylinder twice.

First comes the intake stroke, drawing air and fuel in, and it happens when the piston descends from top dead center (TDC) to bottom dead center (BDC). As the piston travels downwards, it sucks in the air and fuel mixture through the intake valve. The intake valve opens and closes via the camshaft, which has lobes to control how much (valve lift) and how long (valve duration) the valve should remain open during the intake cycle.

Meanwhile, the camshaft turns in sync with the crankshaft and the piston's movements using a timing chain or timing belt. The four-stroke engine is an interconnected system that needs to operate precisely, hence the use of more parts than a comparable two-stroke engine.

Compression improves combustion

After the intake comes the compression cycle, and it happens as the piston ascends from BDC to TDC. Compressing the air/fuel mixture is essential to improving combustion efficiency, and packing the volatile mix into a smaller space helps raise the temperature and pressure inside to squeeze out more energy when it combusts. At this point, the intake valve has closed to seal the chamber. As the piston rises and compresses the air/fuel mixture, the spark plug ignites the mix just before the piston reaches TDC.

More energy means more power, and more power is produced if the piston is pushed harder downwards after the air/fuel mixture ignites. We're slightly getting ahead of ourselves here, but it demonstrates how compressing the air/fuel mixture leads to better explosions and more power down the line.

It's also important to discuss the compression ratio. That refers to the volume of the cylinder when the piston is BDC relative to the volume when the piston is at TDC. In short, it's the max volume of the combustion chamber when the piston is at its lowest point (BDC) divided by the volume when the piston is at its highest point (TDC). For example, an 11:1 (or 11 to 1) compression ratio typically means the piston squeezes the air/fuel mixture into a space that's 1/11th of its original volume at the end of the compression stroke.

Power makes you go

The power stroke begins the moment after the piston rises to TDC and compresses the air/fuel mixture. Right before the piston reaches TDC, the spark plug ignites the entire thing. The controlled explosion that occurs as a result will push the piston downwards.

It's critical to point out that the combustion process is the only one in the four-stroke cycle that produces the actual power we feel when stepping on the gas pedal. As the piston moves downward from TDC to BDC again after combustion, it pushes the connecting rod and rotates the crankshaft, producing the kinetic energy that turns the wheels.

Of course, the engine power feeds to the transmission before the wheels, but you get the point. Meanwhile, the intake and exhaust valves remain closed during the power stroke, but the latter begins opening as the piston descends to BDC.

The exhaust stroke completes the four-stroke cycle

The combustion chamber is now filled with burnt gases after the power stroke. Just as the piston descends to BDC after combustion, the exhaust valve starts opening in sync with the piston rising once again to TDC. As the piston moves upwards, it pushes the spent gases out the exhaust valve and into the exhaust manifold. From there, it travels through catalytic converters and out the tailpipes, completing the exhaust stroke.

The exhaust valve closes the very moment the piston reaches TDC. By that time, the piston will once again descend towards BDC, which marks the beginning of the next intake, compression, and power cycles. Repeatedly managing controlled explosions will eventually take a toll on a four-stroke engine's internal parts, which is why periodic maintenance is critical to maintain operating efficiency while extending the motor's service life.

Things like changing the oil frequently and using the right type while doing so (there's a difference between semi-synthetic, synthetic blend, and full synthetic oils), will increase longevity. As will replacing the spark plugs using the right type and heat range, and periodically changing the engine air filter.