What's The Difference Between Common Rail And Mechanical Injection Diesels?

Mechanical injection systems rely entirely on engine driven components to meter, pressurize, and time fuel delivery. In these engines, a mechanical injection pump is driven by the engine's gear train and performs multiple jobs at once. Pressurized fuel travels through individual high-pressure lines to each injector, where fuel pressure alone lifts the injector pintle and sprays fuel into the combustion chamber.

The amount of injection pressure in a mechanical system is dictated by the speed and load on the engine; the pressure takes a fall whenever there is a decrease in either aspect. This results in larger droplets of fuel that take their sweet time to burn, since fuel does not atomize as finely at lower pressures. Fuel atomization is also affected if your injectors are dirty, so make sure to clean them from time to time.

A delay in combustion increases smoke and makes mechanical systems very inefficient. A mechanical system's normal operating range is just a few thousand psi. This might have been sufficient for engines in a bygone era, but it restricts combustion control in modern models. The call for an injection system that increased injection pressure while optimizing combustion was growing louder, and common rail injection answered by separating the pressurization and injection of fuel.

How common rail injection changes pressure, timing, and control

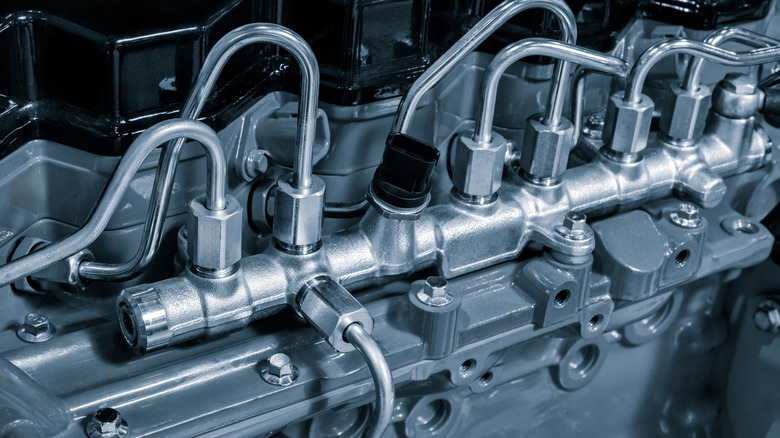

By making one small change, common rail systems solve the problems faced by a mechanical system. The fuel is no longer pressurized at the time of injection;it's already stored at high pressure in a shared accumulator called the rail. The fuel is pumped into the rail and distributed to each cylinder through injectors that are controlled electronically. Instead of being tied to engine conditions, the timing of injections and amount of fuel injected are controlled by an electronic control unit. It's also one of the reasons why modern cars don't need tune-ups anymore.

Injection pressures of tens of thousands of psi are typical under load, which results in a much finer atomization of fuel than a mechanical system. Combustion is improved since the finer mist mixes a lot better with the air. The use of a pressurized rail means high injection pressures can be maintained across the board, even while idling or at low load. Courtesy of the electronic control unit, fuel can also be injected multiple times in a single combustion cycle.

Why the industry shifted and what it means in practice

Mechanical systems might have worked fine for older cars, but they couldn't provide the precise control over injection that modern engines called for. They weren't able to maintain clean and efficient combustion over a wide range of speeds and loads, which meant they couldn't keep up with the call for better fuel economies and tightening emissions standards (although, recently, officials have been arguing that those standards don't make any difference for the environment). This is what eventually pushed manufacturers away from mechanical systems and towards common rail systems.

Common rail systems allow injection pressure to remain largely independent of engine speed, which stabilizes combustion even when a car is idle. This eliminates the characteristic smoke seen in mechanical engines under light load and allows engines to run smoothly at very low speeds. The ability to precisely control timing and injection rate also reduces wasted fuel and lowers particulate emissions.

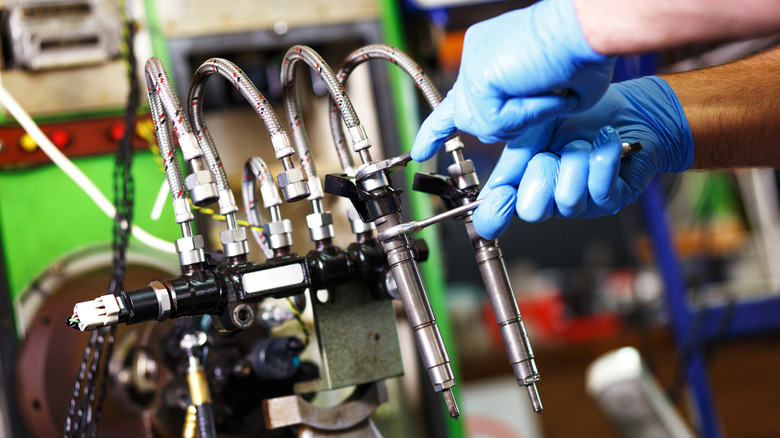

These benefits come with tradeoffs, though. Common rail systems are more complex, operate at extremely high pressures, and are far less tolerant of contaminated fuel. Servicing requires strict safety procedures, and fuel quality becomes critical, as the fuel itself is used to lubricate highly-precise components.