Long- Vs Short-Stroke Engines: What Are The Differences?

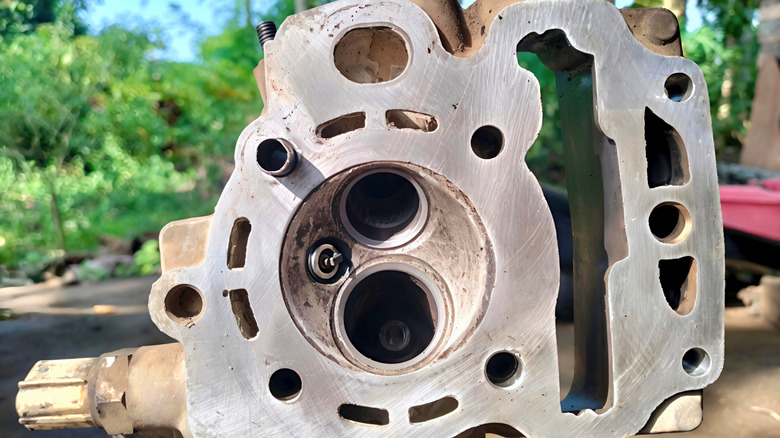

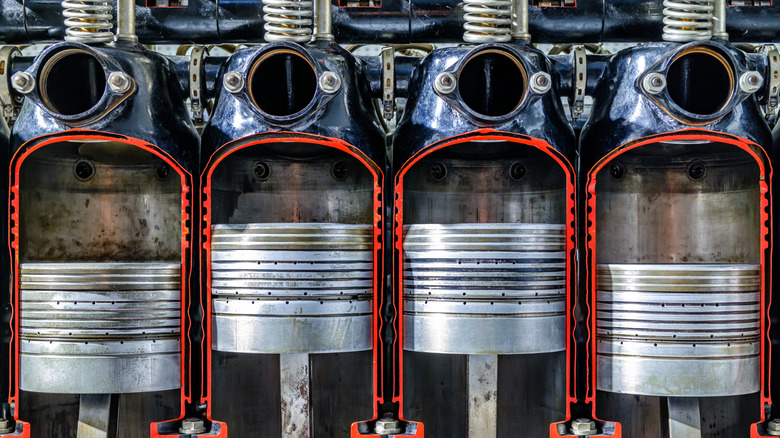

Just about every piston engine is defined by two basic measurements: bore and stroke. Bore is the diameter of the cylinder. Stroke is the distance the piston travels from bottom dead center to top dead center. Introduce a bit of math, including cylinder count, and those measurements eventually lead us to the overall displacement of an engine.

When bore and stroke are equal, the engine is described as "square." A long stroke is called an undersquare, meaning that the stroke is significantly longer than the bore, and a short stroke is called an oversquare, meaning it has a bore larger than the stroke.

When comparing long-stroke and short-stroke engines, and their associated benefits and drawbacks, it's useful to compare engines of equal displacement. That way, we can talk about the changes in bore and stroke as they relate to each other, and how those differences in engine design have effects on power, efficiency, and packaging.

Stroke length and stress inside the engine

An increase in the distance a piston travels inside the cylinder, aka the stroke length, also increases the stresses acting on the piston and crankshaft. The longer the stroke, the more inertia has to be managed inside the cylinder. This is one of the main reasons why long stroke engines are not designed to rev very high.

A short-stroke engine has less inertial stress. Since the piston has less distance to travel, the acceleration of the piston is lower at the same rpm. All other factors being equal, this means that the engine can rev to a higher rpm before stress becomes a limiting factor. Short-stroke engines have an advantage where engine manufacturers are looking to maximize power, because power output is directly linked to engine speed — higher rpm means more horsepower. Some of your favorite high-revving supercars likely have short stroke.

However, engine speed isn't the complete picture. Stroke length also affects valve timing and combustion behavior, all of which shape performance.

Breathing, valves, and combustion chamber shape

So, the bottom end of an engine, with its cylinders and crankshaft have inertial stresses to deal with. Then, there's the effect bore has on the top end and components like valves. Larger bore cylinders have more room for valves, which regulate the flow of air and fuel into the combustion chamber. Larger valves allow for increased airflow into the cylinder.

Short-stroke engines directly benefit from this. Since their larger bores result in better breathing, they can create power at higher rpms. The opposite happens with long stroke engines. Since they have smaller bores, their valve sizes and resulting air flow is limited. Generally, this limited airflow is what makes long-stroke engines limited in their production of power.

There are also the effects that bore and stroke have on turbulence. Turbulence is basically the movement of the air-fuel mixture inside the cylinder. Smaller bores and deeper chambers hold longer turbulence and give faster combustion. Cylinders with larger bores and flatter chambers promote quick decay of turbulence. Earlier ignition timing is required to counter that, but that is also a double-edged sword, since it exposes the piston crown and the cylinder head to heat for longer periods. This increase in exposure can lead to an increase in heat loss and a decrease in efficiency.

Torque, efficiency, and common misconceptions

A persistent belief is that long-stroke engines inherently produce more torque. That is not always true. Differences in bore and stroke result in changes in pressure, as well as lengthening or shortening of the effective lever arm, and those effects cancel each other out when the displacement stays the same. So stroke length by itself does not determine torque.

What does differ is where torque is produced. Ever heard the term "low-end torque"? Long stroke engines typically reach their peak torque at lower rpm. Smaller bores and valves limit high speed breathing, but the combustion process is well suited to lower engine speeds and a strong torque delivery at low rpm. This is why, when most people think of long-stroke engines, they think of relaxed performance at low speeds. This is also part of the reason why semi trucks don't use V8s, as the low RPMs put less strain on their engine, increasing reliability and decreasing operating costs.

Friction, cooling, and mechanical losses

As bore and stroke vary, so does friction. A longer stroke increases piston travel distance, raising friction. By limiting the distance a piston has to move, short-stroke engines have reduced friction and windage. Windage is the air resistance that the piston faces as it moves inside the cylinder, and like friction, it can cause loss of energy inside the engine. Another way short stroke engines manage the loss of energy is with a smaller crankshaft throw, which results in rotating components moving through a smaller arc.

Another issue to keep in mind is cooling. If the surface area of a piston is smaller, it's easier to cool. But as bore size increases, so does the distance heat must travel from the piston crown to the cylinder wall.

Long stroke engines with smaller bores benefit from easier piston cooling and reduced heat concentration. There's clearly a balance between these two dimensions: bore and stroke. Each has its benefits and drawbacks, and automakers have to design engines with all the science and math in mind.