What's The Difference Between Single And Dual Overhead Cam Engines?

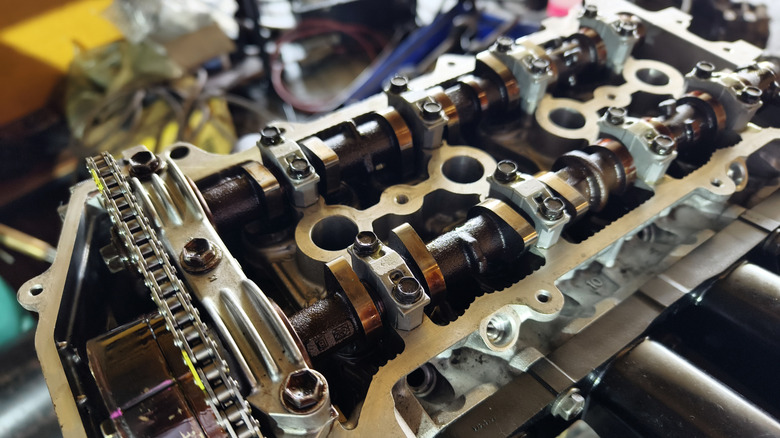

Camshafts are simple devices, but important ones. Modern engines can have one or more intake and exhaust valves, and it's the camshaft's job to open valves precisely as the engine runs, supplying the air and fuel required for smooth and efficient operation. The camshaft regulates the opening and closing of the valves using lobes, or raised sections in the assembly. It turns in sync with the crankshaft, which is connected to the pistons inside the engine block, via a timing belt or timing chain.

Many engines are commonly referred to as overhead cam (OHC) engines, or those with camshafts on top of the valves and combustion chamber. These types of engines are different from pushrods or overhead valve (OHV) engines, where the camshaft is inside the engine block. Although there are still a few modern trucks you can buy with OHV motors, most auto engines feature OHC configurations with either single or dual camshafts.

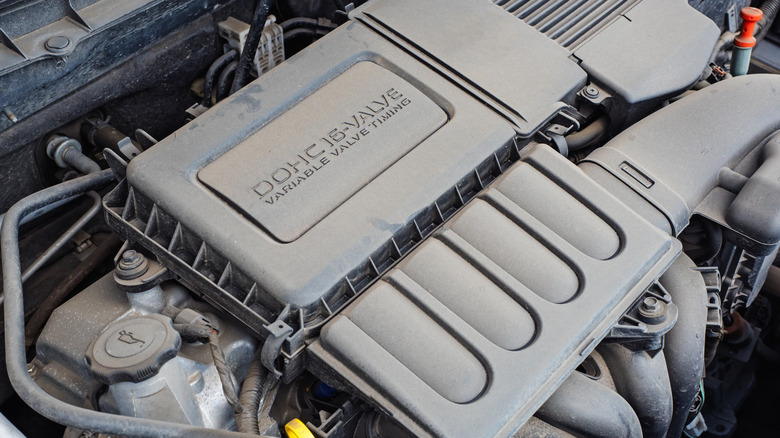

The primary difference between a single and dual overhead cam engine is the number of camshafts inside the cylinder head. In a single overhead cam (SOHC) engine there's only one camshaft to govern the intake and exhaust valves, while engines with dual overhead camshafts (DOHC) have two: One for the set of intake valves and another for the exhaust valves.

SOHC versus DOHC: Is one better than the other?

There are pros and cons to SOHC and DOHC engines. Motors with a single overhead camshaft tend to have two or three valves per cylinder, but there are SOHC motors with four valves per cylinder. Despite having more restricted airflow, SOHC engines tend to produce more low- to mid-range torque. SOHC engines also have fewer parts, which makes them more economical to manufacture and easier to repair. What's more, single overhead cam engines tend to weigh less thanks to their simpler construction. Despite that, SOHC engines are limited in the performance stakes, but the mid-range grunt makes them useful in certain situations.

On the other hand, engines with dual overhead camshafts (DOHC) typically have more complex designs and moving parts, making them costlier to manufacture and a bit trickier to disassemble and repair when something goes wrong. And since DOHC motors have more parts, they are also costlier to produce. However, most DOHC engines have four valves per cylinder to improve the airflow and volumetric efficiency, enabling them to produce better horsepower and spin faster. Moreover, DOHC makes it more feasible to integrate variable valve timing technologies that enable smaller engines to have more muscle while sipping less fuel.