Here's How 'Bulletproof' Car Windows Are Made

When contemplating a new vehicle, the average buyer may research which popular car brands are known for their safety. As such, they might ignore how ordinary automotive glass is a techno-chemical marvel made to withstand harsh conditions, suppress noise, and protect occupants. Ballistic glass — the stuff of "bulletproof" car windows — has to (obviously) account for specific forces far and above standard automotive glass, but it relies on some of the same manufacturing principles seen in windshields.

"Standard" automotive glass is not one type of glass. It's engineered to different specifications depending on where it's used in a vehicle. Rear- and side-window glass is usually tempered, meaning it's fabricated using a thermal process that heats the glass up to temperatures above 600 degrees Celsius as it's made. This makes it four to five times stronger than regular glass while allowing it to shatter into small pieces outward from the vehicle, reducing injury risks for passengers.

Windshields go even further. On top of providing UV and debris protection, they also grant structural rigidity and rollover integrity. They're also the first thing a passenger airbag hits when it deploys. Windshields are typically a laminated sandwich of materials, and they're designed not to shatter thanks to a sheet of polyvinyl butyral (PVB) resin pressed between sheets of glass for strength and flexibility.

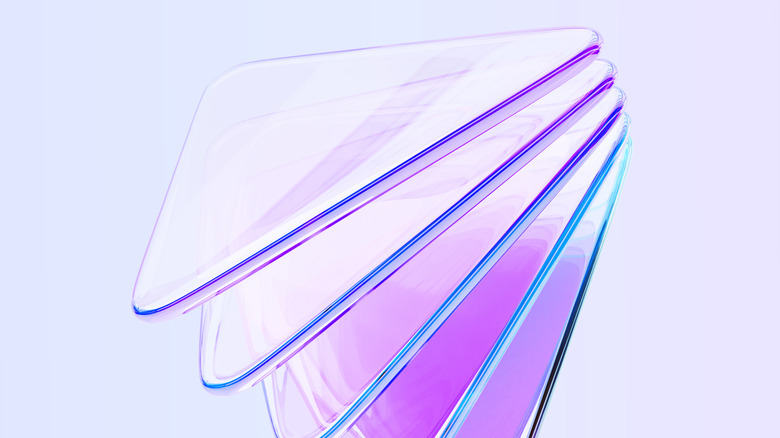

Bulletproof glass — or, more accurately, bullet-resistant glass — takes similar cues from windshields. Instead of being roughly 3mm thick, though, bulletproof glass can reach 39mm or more, featuring several layers of glass, polycarbonate, and/or acrylic sheets engineered to absorb energy and keep occupants safe from harm.

Bullet-resistant versus bulletproof

Bulletproof is a common term used to describe any glass that can stop a bullet, but technically, resistance levels depend on what specification the glass meets. Things like firearm types, ammunition, and bullet speed can vary, so it's impossible for all glass to be completely impenetrable. There are industry standards — such as UL 752 — that guide how much resistance layers of glass, PVB, and other composites provide. This is why manufacturers will point out that "bullet-resistant" is the proper term — even though "bulletproof" is the term used to discuss the technology.

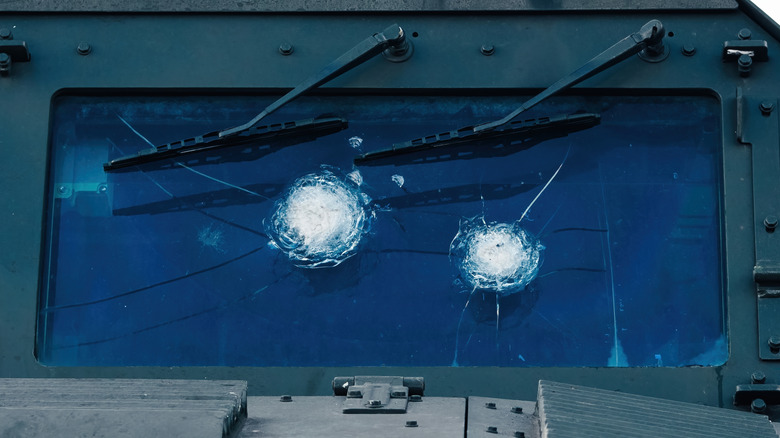

When it comes to stopping a bullet, bulletproof glass is meant to absorb the impact. In sports that require athletes to pass and catch — like, hockey, lacrosse, baseball, and American football — having "soft hands" means being able to bring a moving puck or ball safely under control. This is exactly what bulletproof glass does, as its layers of glass and plastic work together to soak up a bullet's momentum. The hard outer shell of glass or acrylic is the first barrier that deadens a bullet's initial impact, causing it to deform and lose speed. If that's not enough to stop the bullet, the next layers will absorb the bullet's travel.

Made to bend, but not break

Different manufacturers may use their own proprietary formulations and layer compositions, but the general idea of softer middle layers in bulletproof glass is the same: bend, but don't break. If a bullet makes it through the outer shell, these bonded inner layers will flex and act like a net that harnesses the bullet's momentum. Each layer helps to spread the bullet's force out until it dissipates, making it stop.

These capabilities can come with compromises. The thicker the shell, and the more layers involved, the more difficult the glass may be to see through – and the heavier it may be. Many standard automotive windshields weigh around 25 pounds. For a windshield that could withstand some of the highest caliber rifle shots, that weight is closer to 500 pounds. That heaviness could require extensive modifications of the frame, hinges, and other components. But as technology evolves, some manufacturers are offering lighter designs that are even transferable between vehicles.

The creation of bulletproof car windows is just one part of the armored vehicle equation. The rabbit hole of armored vehicle design can offer a speculative window into the first presidential limo, and it shows how Volvo ratcheted up its safety heritage by turning its XC60 and XC90 from normal SUVs into armored cars you can buy.