Why Do Some Engines Use Hydraulic Lifters?

The engines of yesteryear were pretty simple, with tappets clackity-clacking away on cam lobes, opening valves, and making a ruckus while doing it. Mechanical lifters were adequate for valve operation, but they required a small clearance, or lash, that needs periodic adjustment. They're also noisier and wear more over time. Hydraulic lifters, on the other hand, solved some of these problems. They contain an internal piston and use engine oil to maintain zero lash automatically, running quieter with less maintenance but relying on clean, proper lubrication.

Hydraulic lifters first appeared in the 1930s, but they didn't truly take off until Cadillac used them in its legendary V16. That engine proved an irresistible turning point, showcasing that a lifter that maintains zero valve clearance on its own makes the engine smoother and far easier to live with. Soon enough, solid lifters started being phased out, with only a few automakers still sticking with them nowadays.

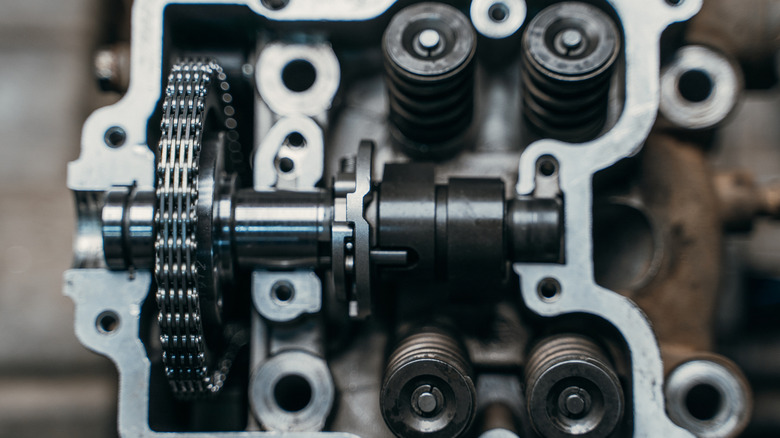

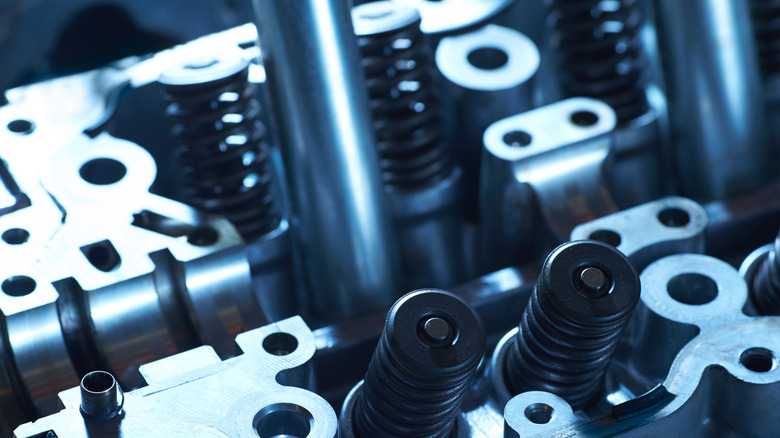

How a hydraulic lifter actually works

When an engine runs hot, it results in the internal components expanding due to the heat. To account for this expansion, a little clearance is needed. With overhead cam engines, that clearance is needed between the tips of the rocker arms and the tops of the valve stems. That clearance is called lash. But it needs to be just right. Too narrow, and the valve seating would be improper, causing compression problems and torched exhaust valves. Too wide, and you look down the barrel of reduced engine performance and increased noise. Wear on the valvetrain means this clearance needs to be constantly monitored and adjusted for optimal performance.

Racing engines also rely on lash adjustments to fine-tune power. Tighter lash (or less clearance between the components) increases lift and duration for high RPM gains. More lash decreases lift and improves low RPM response. Hydraulic lifters avoid routine lash checks, but they still need an initial adjustment so the plunger operates in its mid range.

Why engines with hydraulic lifters run quieter

Despite the name, a hydraulic lifter isn't a tiny oil pump. It's more like a self correcting spacer with an oil pressurized piston inside. As the camshaft rotates, each lobe's rising and falling profile pushes the lifter in a precise pattern timed to its cylinder, transferring motion through the pushrod to the rocker arm. When the lifter rides on the cam's base circle, oil fills the internal cavity and raises the piston. As the lobe lifts, a check valve traps the oil, making the lifter act solid so it can open the valve. Once the lobe passes its peak, pressure drops, fresh oil refills the chamber, and the cycle repeats smoothly and quietly.

If proper oil pressure (here's what's considered healthy) and clean lubrication are maintained, this constant cycle will ensure zero lash for the entirety of the engine's lifetime. It's plain old clever engineering, but it frees us all from the hassle of constant manual tweaks.

Maintenance advantages and real world reliability

To recap: the singsong tapping or ticking sound, sometimes called valve clatter, is common in mechanical valvetrains. The culprit behind that noise is lash, the small space that transiently closes as the cam takes up slack and snaps the valve open. Hydraulic lifters eliminate that gap, maintaining zero clearance at all operating temperatures. This reduces the hammering effect that occurs when closing valves repeatedly smack the valvetrain hardware at high RPMs. Due to the valves not having to fill an air gap, they can simply follow the cam lobe and close gently, resulting in quieter operation, and extending the life of the rocker tips, valve stems, cam lobes, and pushrods, since they don't wear as much.

Despite all of their benefits, hydraulic lifters are not invincible. Oil contamination, low oil pressure, or aerated oil can cause a lifter to collapse, increasing lash and producing that classic ticking sound. Here's how to keep them quiet if that ever happens. A faulty check valve inside the lifter can also bleed pressure too quickly or fail to hold pressure at all. But with clean, quality oil and regular service intervals, hydraulic lifters are extremely durable.

These days, consumer expectations and emissions regulations have forced nearly all modern production engines to use hydraulic valve lifters. In a world where both buyers and regulators want peace and quiet when driving, hydraulic lifters are a no-brainer.