Here's How Marine Alternators Are Different From The One In Your Car

One of the critical components of a vehicle's electrical system is the alternator. In a car, for instance, the energy that powers things like the audio system, climate control system, and headlights is pulled from the alternator while you're traveling. The alternator also helps keep the battery charged, which lets you start the engine.

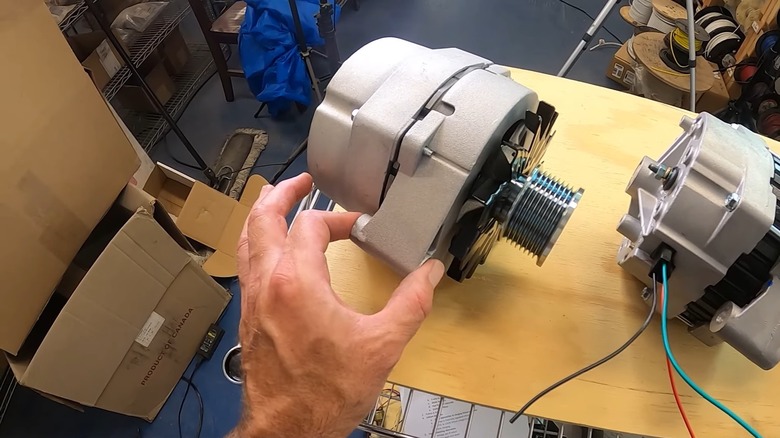

A boat engine also has an alternator that performs many of the same functions. However, it's not the same as the one under the hood of your car. And these distinctions aren't limited to the alternator, as marine and automotive engines have many differences. Powering a watercraft requires an approach unlike that of an automobile, as the environments and conditions present different challenges.

While they may serve a similar function, marine alternators are built to handle greater demands than a car's, are made of materials that resist corrosion, need more robust cooling, and must include additional safety features.

Energy demands and corrosion

Automakers continue to stuff more technology into their vehicles in the form of displays, additional lighting, and driver assistance equipment. In fact, even this isn't enough — people apparently want more screens inside their cars.

However, these energy requirements still pale in comparison to those of many watercraft. A vessel, too, could be packed to the brim with the latest technology. In addition to the navigation system and lights, a boat may have a battery bank, radio equipment, pumps and more, with an alternator working to support the batteries. In general, while a car's alternator may generate 40 to 120 amperes, a marine version will push 300 amps.

Larger vessels can even have appliances such as refrigerators and stoves as well as other modern amenities, putting them on par with a luxury home. Take for instance, this retired Dutch Navy ship reborn as a $24-million yacht, which comes with a hot tub and humidity-controlled cigar room. Suffice it to say, your car's alternator wouldn't be up to the task of supporting a boat, as it wouldn't be able to replenish the cranking battery quickly enough, let alone support additional house batteries.

Your car's alternator is also protected from getting wet and operates in a dry environment. A marine alternator has to be made from like stainless steel and coated in robust anti-corrosion layers to prevent rust from forming.

Cooling and ignition prevention

Another way a marine alternator differs from the automobile version is in how it keeps cool under load. An alternator generates energy by spinning an electromagnet. This contributes to heat generation, as does the conversion of mechanical to electrical energy.

Under a car's hood, alternator thermals are often managed with multiple fans. However, a marine inboard engine is sealed within a compartment in the vessel, meaning air cooling doesn't work as well. So a marine alternator may be equipped both with multiple fans and with sizable heat sinks to manage temperatures.

The enclosed environment of an engine room isn't just problematic in terms of cooling, it's also a contributor to potentially hazardous situations. To prevent fires or worse, U.S. Coast Guard safety standards require marine alternators to have something called a spark screen or spark arrestor installed. This mesh confines any sparking from the component so it won't become an ignition source for flammable gas.