Yes, Chrysler Tried Four-Wheel Disc Brakes In 1949 (But They Weren't What You Think)

In the early days of the automobile, there weren't really prescribed ways of doing things the way there are now. Auto manufacturers frequently experimented with a variety of new technologies to gain a competitive advantage, either for the road going customer, or the race track. In 1949 Chrysler debuted a unique method of slowing down its large stately machines, a new form of disc brakes. Now de rigueur, disc brakes were relatively new tech in 1949, having debuted on aircraft during World War 2. Crosley, somewhat poorly, adapted airplane brakes for the tiny HotShot sports car, but they weren't ready for the rigors of automotive use and the plan was scrapped almost as quickly as it began. Chrysler, meanwhile, took a different tack with its braking system, developing a new style of brake pads that look more akin to a clutch disc, expanded between two spinning iron friction surfaces. This is completely different and distinct from Porsche's unique annular disc brakes, as well.

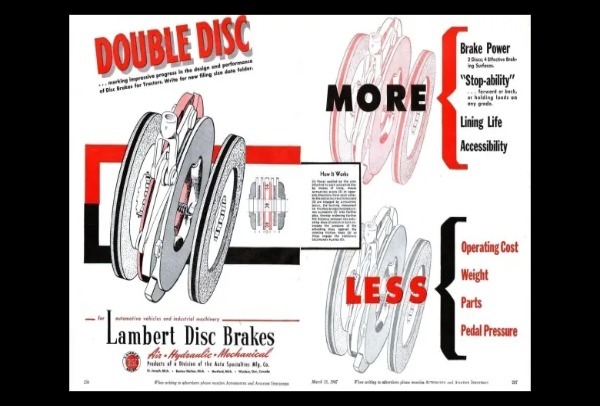

The system Chrysler employed was developed by Automotive Specialties Manufacturing Company (AUSCO) under patents filed by engineer Homer L. Lambert, and first tested by the company as far back as 1939. Considered a self-energizing system, in that it employed some of the braking energy to increase braking effort, this Ausco-Lambert setup made for better braking in the large Chryslers with minimal effort expended by the driver. This system also allowed for a reduction in brake fade, cooler operating temperatures, and employed a much larger friction surface when compared to Chrysler's then-standard twelve-inch drum brakes. Ultimately, while the brakes provided significantly better braking power and could be counted on for repeat use, they were significantly more expensive than drums or caliper-and-disc style brakes, while being grabby and overly sensitive.

So how do they work?

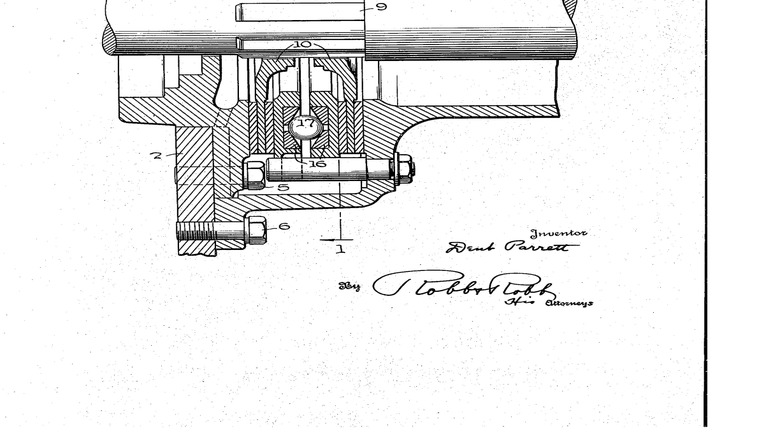

The Ausco-Lambert system doesn't work anything like the disc brakes on your family crossover. Instead of a pair of friction brake pads clamping on a spinning metal disc brake surface, Lambert employed what he called a "double disc," which sandwiched a brake pad plate between a metal friction surface casing that spun with the motion of the wheels. and an axle-mounted spinning metal surface. From the outside the system looks a lot like an overly finned drum brake, but it's what's inside that counts. When the driver applied the brakes a pair of wheel cylinders in each corner pushed a split friction disc apart to make contact with the insides of the spinning housing. Each friction disc employed six steel ball bearings inside, riding in a ramp that helped push the wedged disc apart. Strong metal springs helped return the friction surface together when the driver let off the brake pedal.

The so-called double disc braking system was only available from Chrysler as standard on the extended Crown Imperial limousine through 1954, and on the one-year-only 700-unit limited production 1950 Town and Country Newport. The system was made optional on other Chrysler machines, but at an exorbitant $400 price tag, or around $5,400 in 2026 dollars when adjusted for inflation. It's safe to say very few customers took them up on the offer.

It would still be a few years before Jaguar and Dunlop finally perfected the disc brake for use in automobiles, famously using a prototype system to win the 1953 24 Hours of Le Mans with Tony Ralt and Duncan Hamilton sharing driving duties of the #18 C-type. The rest, as they say, is history.