What Causes Exhaust Manifold Bolts To Break?

We may receive a commission on purchases made from links.

An engine relies heavily on air to make the combustion process work properly. The exhaust manifold, which is attached to the engine block, consolidates all of the separate expelled cylinder gases, allowing them to proceed down the chain of exhaust components. Performance versions of this part are just one example of mods that actually make your car faster. Unfortunately, the bolts that hold the exhaust manifold secure can fail. In fact, this is one of the issues that plague some of the Ford V10 Triton years with the most problems.

Intense thermals put these fasteners under tremendous stress. Exhaust manifolds can reach up to 1,200 degrees Fahrenheit under typical circumstances, and this heat causes the metal to expand. However, as soon as these high temperatures abate when the vehicle isn't running, the metal then contracts as things cool under the hood. To combat this flux of expansion and contraction, materials like stainless steel or cast iron are used to make the manifold capable of enduring this punishing process. The bolts holding the part in place, though, can eventually break after hundreds of extreme thermal cycles. This issue is exacerbated when towing, as the exhaust manifold can become visibly red with heat extremely quickly.

What happens when exhaust manifold bolts fail?

Negative affects can result from even a single broken exhaust manifold bolt. Not only are the exhaust gases extremely hot, but they're under tremendous pressure as they're released into the exhaust manifold. These gases come in pulses, not a continuous flow. Once a single bolt breaks, the previously tight seal and gasket affixing the part to the engine block become compromised. You may notice ticking or hissing noises, particularly when first starting the engine, as some of that hot pressurized gas is escaping the exhaust manifold. Exhaust gases are toxic, so if they're able to find a way into the cabin it could be dangerous for the vehicle's occupants.

That's not the only issue either, as you can also experience dips in performance and efficiency, as well as odd odors from your engine. As these gases exit the cylinders in pulses, a leaky exhaust manifold can also permit air to enter. Modern engines are governed by a range of sensors that can identify changing conditions and make corrections. With bits of outside air combining with the exhaust, the engine can begin adjusting the fuel mix by adding more gas or diesel to compensate for what it perceives as an imbalance of too much oxygen.

With at least one bolt failure, the exhaust manifold can eventually warp, making the problem worse. In addition, common sense would tell you the remaining bolts are under greater stress than usual, as they will be picking up the slack left by the broken bolt. This could lead to more bolts potentially breaking off in the future.

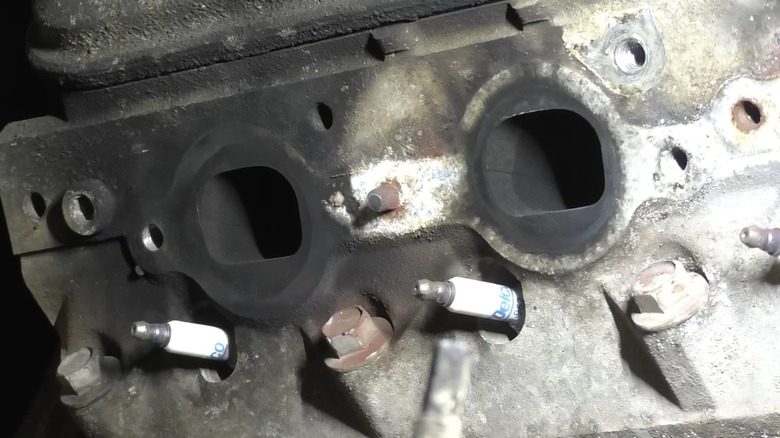

Removing exhaust manifold bolts is a process, especially if they're broken

Older and untouched exhaust manifold bolts can become heavily corroded. That can make even an intact fastener difficult to remove. One way to help prevent one of these bolts from snapping as you're attempting to twist it loose is to apply a penetrating solvent like CRC Knock'er Loose. This will help break up corrosion that can make bolts locked up and stubborn to move. The process may need to be performed repeatedly over the span of a few days in some scenarios. In addition, there are a variety of other ways to remove a stuck bolt without breaking it, such as heating or tapping on it, to name a few.

If an exhaust manifold bolt is already snapped and the thread is sticking out, you have some options. For example, the YouTube channel South Main Auto LLC demonstrates one method in their video, "Removing Broken Manifold Bolts The Easy Way!" Essentially, it involves scrapping away some of the buildup around the thread, screwing on a nut, and then welding the nut and stud together. This provides a hexagonal head to grab onto, allowing for straightforward removal. Unfortunately, if the broken bolt is flush or snapped inside the part, you'll have to consider drilling and using an extractor to remove it.