What Is A MAP Sensor And How Can You Tell If It's Bad?

Internal combustion engines create power by mixing air and fuel, compressing the mixture, and igniting it. In more technical terms, most engines go through four strokes: an intake stroke, a compression stroke, a combustion (power) stroke, and an exhaust stroke. During all of these, various sensors and control units manage the amount of air and fuel entering the engine. If the mixture is too lean or too rich, with too little or too much fuel, combustion will be inefficient. This can waste fuel, cause the engine to misfire, and even lead to catalytic converter problems.

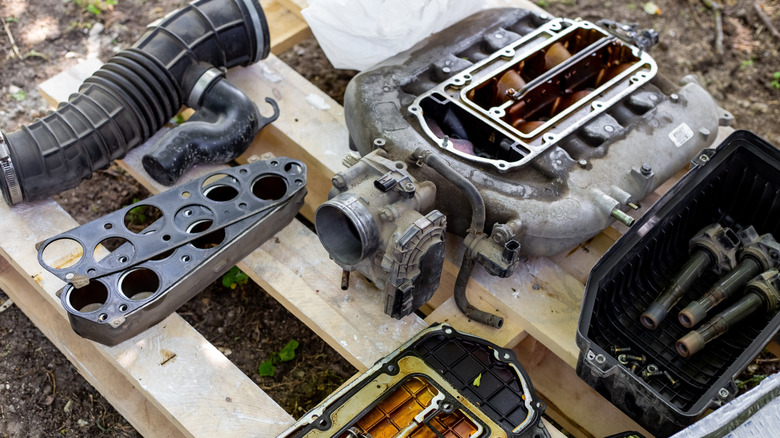

One key sensor in this process is the Manifold Absolute Pressure (MAP) sensor, whose primary role is to measure the absolute pressure — that is, the pressure as it compares to a vacuum — inside the intake manifold. Once this data is collected, it is sent to the engine control unit (ECU), which uses the information to figure out the air's density, helping it determine the amount of fuel to inject and also to adjust ignition timing. Because of this, the MAP sensor is crucial for maintaining an efficient, consistent air-fuel mixture. Here's how you can tell if it's failing and what to do about it if it is.

Inner workings of the MAP sensor and what can go bad

Once power is needed, the intake is going to let more air in. As Engineering Explained says, "When you press on the gas pedal, you're going to increase the pressure inside the intake manifold. There's going to be less of a vacuum. ... When there's less of a vacuum, it's going to push up on that silicon chip and force it to flex upward. And when it flexes it upward, it's going to alter its resistance."

The MAP sensor acquires data by flexing its diaphragm in response to that pressure. The ECU receives this signal and determines fuel delivery and timing. So what can go bad? The wiring and its connectors can corrode, or become frayed or loose. This can mess up the data the MAP sends, leaving the ECU unable to alter the mixture properly. Think of it like a cooking assistant miscommunicating with the head chef: if the assistant sends bad information, the chef might add the wrong ingredient, and the dish won't turn out right.

The chip can also get damaged or contaminated by oil, dirt, and water. A hose connected to the intake manifold could be leaking, which can cause the MAP to send incorrect data even though it works just fine. The sensor can also drift, and it can get damaged by extreme temperatures within the engine bay. Lastly, the MAP might be working right, but the ECU might still misinterpret the data it receives — just like in some diesel engines that feel sluggish under load.

Troubleshooting and fixing a bad MAP sensor

A check engine light that keeps coming on after clearing can be a sign of a failing oxygen or MAP sensor. Also, since a malfunctioning MAP sensor messes up the air-fuel mixture, it can lead to rough idling, engine knocking, misfires, or poor fuel economy. It can also lead to reduced power, stalling, hesitation, black smoke from the exhaust, higher engine temperatures, a failed emissions test, or difficulties starting the engine.

To fix these problems, go over all of the potential culprits first. Check the connectors, wires, and potential vacuum leaks, and look for contamination. It's also a good idea to use an OBD-II reader to scan for potential fault codes. If all of these are fine, test out the sensor's resistance or voltage by using a multimeter. Also, be sure to check related sensors, such as those for the intake temperature, throttle position, and engine coolant temperature. All of these work alongside the MAP to help the ECU do its job. Lastly, if you can't notice any problems with these, wiggle the sensor a bit and test out the ECU.

When all of this troubleshooting is done, it should give you a clear culprit. If it's the sensor, although cleaning it can help, it's better to replace it. After replacing it, clear fault codes and give the car a test drive. If you're still experiencing problems, take the car to a professional.