Why You Should Never Reuse A Cylinder Head Gasket

A cylinder head gasket forms a seal to prevent leaks between your engine's cylinder head and the engine block. It must contain the immense pressures created by the combustion cycle and seal the joint well enough to prevent engine oil and coolant from seeping beyond their respective passageways. As a general rule, gaskets are among the car parts you should never cheap out on. However, with a set of quality head gaskets for a common V8 engine commonly priced above $100 — and some head gasket prices going over $1,000 — sometimes it's hard to justify the cost for such a mundane part.

As the cost of rebuilding an engine rises, it becomes easier to justify reusing a head gasket that still looks like it has some life left in it. However, it's not a good way to keep costs down. Dragzine sums up the situation nicely, mentioning that "if a head gasket is compromised, all kinds of bad things will happen in a hurry that will hurt an engine and the owner's wallet."

While some situations can seemingly make it preferable to reuse a head gasket, a new one is almost always the correct choice. Even if a used head gasket appears pristine, once it's been used, it loses its ability to fill any irregularities between the head and the block. Confusion around the issue likely comes from reusing a head gasket after it was installed to check for clearance, or the practice of reusing a gasket on a race car at the track.

The science behind cylinder head gaskets

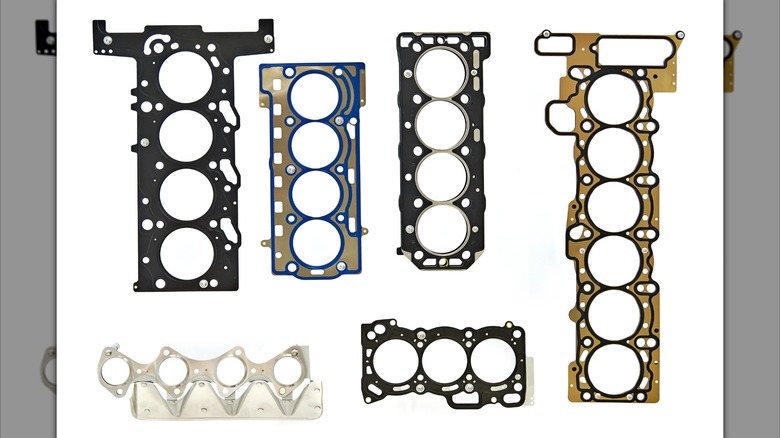

Depending on the make and model of your car's engine, there are various different materials that its head gasket could be made from. As mentioned previously, the head gasket fills the space between the cylinder head and engine block. If it fails, your car could experience a number of symptoms, such as white sludge under the oil cap or white smoke from your exhaust.

Gasket manufacturers produce multi-layered steel (MLS) head gaskets using a variety of materials, including different types of steels and coatings. Some of these MLS gaskets use specialized layers to limit compression around the combustion chamber while they're being installed, helping to improve reliability. Dobson Gaskets, located in the United Kingdom, says "the best material for a head gasket often depends on the specific requirements of the engine." This company in particular produces head gaskets made from MLS, graphite, copper, and composites that can include combinations of graphite, asbestos, or aramid fibers. You can even get your hands on custom gaskets for your classic car, so there's no need to rely on an old one.