Suzuki Once Spent $110 Million To Develop An Engine Only To Shelve It A Year Later

We have all heard about automotive failures, including the Chevrolet SSR, Chrysler's TC by Maserati, and — more recently — Jaguar's entire rebranding fiasco. While the biggest fumbles of automotive legacies stemmed from grandiose visions, there were rare ones that failed because they were almost perfect. One such story comes from India, as reported by Autocar India, where Maruti Suzuki (as the Suzuki brand is known there) spent five years and 1,000 crore rupees (around $110 million) to develop an engine. This engine was then only used in two of its India-specific models before being discontinued just one year later.

It was a 1.5-liter diesel engine intended to replace the aging 1.3-liter diesel sourced from Fiat — a marvel of engineering with clever technology that eventually turned into a ticking time bomb. It turned into such a nightmare that the Indian carmaker quietly pulled it off the market and completely washed its hands of diesel engines. One of the most prolific and prudent carmakers in India ended up with a brand-new and very expensive engine that could not be used.

A logical decision

Coming out with its own engine made sense. The late 2010s covered an era when emissions weren't as stringent, and diesels were preferred for their significantly lower running costs compared to gasoline. But Maruti Suzuki did not have a diesel engine of its own at the time. It used the famed 1.3-liter DDiS diesel engine from Fiat — a collaboration that lasted 12 years and covered 30% of Maruti Suzuki's overall sales at that time.

However, this engine collaboration was an expensive proposition for the brand, and it was about to get even costlier if they wanted to keep on using it. Upcoming emission norms meant the engine would have to be recalibrated, and getting that done could attract outrageous licensing fees. For example, an ECU calibration could reportedly cost close to 10 million euros. Having its own engine would give Maruti Suzuki freedom from those fees and while also granting a strong foothold in the Indian market. Thus, Maruti Suzuki introduced the 1.5 diesel. It appeared in the company's Ciaz sedan in March 2019 and in the Ertiga MPV a month later.

An impressive piece of machinery

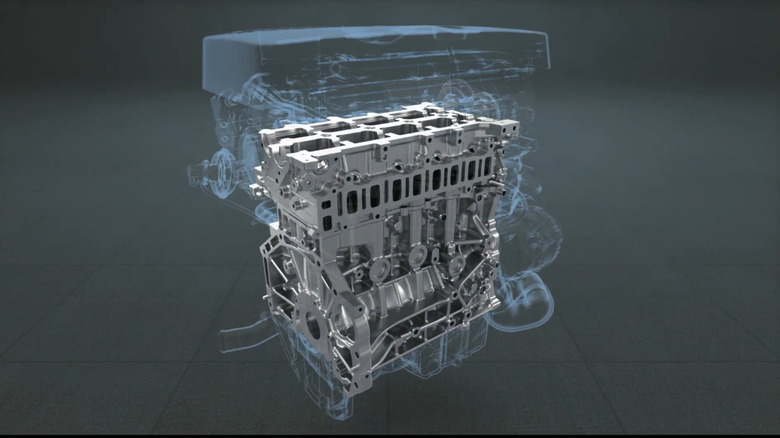

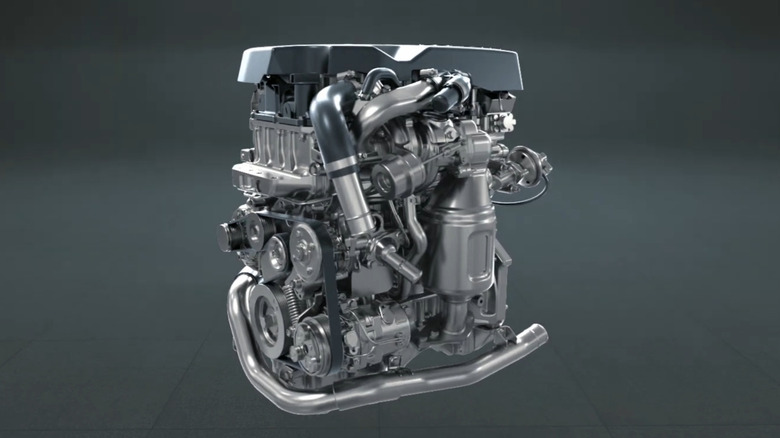

The new 1.5-liter diesel engine (codenamed E15A) was not Maruti Suzuki's first diesel engine. That would be the 793cc two-cylinder diesel (codenamed E08A), which was part of the automaker's ambitious plans of launching two-cylinder, three-cylinder, and four-cylinder diesel engines. It was quickly forgotten for being slow and unrefined in its short two-year shelf life. However, the E15A can still trace its roots to that earlier two-cylinder, as the four-cylinder block was made by practically fusing together two resized E08A engines.

That's where the similarities ended. The four-cylinder motor featured a more robust cylinder block, a dual-mass flywheel, and even a new exhaust manifold. Maruti Suzuki went all out on this engine, and it showed. Unlike the rattly E08A the E15A impressed those who reviewed it during its short year-long tenure. Reviewers were positive over the new engine's refinement, responsiveness, and segment-best fuel economy of 63 miles per gallon.

A cool head

As mentioned, the E15A featured an integrated exhaust manifold. This design, mostly used in newer gasoline engines, has the exhaust manifold as a part of the cylinder head instead of being bolted on separately. There are a lot of benefits to having an integrated manifold like this. For example, its presence inside the head reduces engine warmup times, which improves fuel economy, heats the passenger cabin faster, and improves the efficiency of the air-conditioning system. That integration also makes the engine more compact, allowing for more space in the cabin.

This setup also makes it so the engine's water jacket can cool the exhaust manifold. In a traditional gasoline engine, higher exhaust temperatures can potentially damage the catalytic converter core. The ECU counters this by injecting a richer air/fuel mixture to cool down the combustion process and exhaust gas temperatures. With an integrated exhaust manifold, exhaust gas temperatures drop by around 176 degrees Fahrenheit, negating the need for an enriched air/fuel mixture. This can potentially saves up to 20% of fuel when driving on highways.

There is a good reason why modern gasoline engines work well with an integrated exhaust setup. This isn't the case with diesel engines, though. Compared to gasoline engines, diesel engines fundamentally run cooler, which also translates to cooler exhaust gas temperatures. So while the E15A engine's integrated manifold setup did reap the benefits of better packaging, the impact on fuel economy wasn't as substantial compared to a gasoline engine using the same tech. In fact, that tech posed an insurmountable problem.

What went wrong?

The launch of the E15A (also called the DDiS 225) in the Ciaz was very close to the looming BS6 deadline. Bharat Stage 6 (BS6) was India's emission equivalent to the stringent Euro 6 emissions norms, which primarily focused on nitrogen oxides and particulate matter emissions. With the deadline set on April 1, 2020, Maruti Suzuki had the tough task ahead of getting its BS4-compliant engine ready for the upcoming BS6 norms. (For clarification, India skipped BS5 and jumped from BS4 to BS6)

While the BS4 diesel vehicles used a Diesel Oxidation Catalyst, the switch to BS6 needed the addition of a complex Diesel Particulate Filter (DPF). A DPF uses a ceramic honeycomb-like structure that filters soot and other particulates from the diesel exhaust by forcing gas through the porous ceramic walls and trapping carbon particles. When full, a process called DPF regeneration effectively raises the temperature inside the DPF enough to burn off the particulates, leaving behind inert ash.

In a conventional diesel engine, the exhaust gases exit at a temperature high enough to keep the unburnt fuel in a gaseous state, letting it pass through the DPF's fine sleeves easily. With the E15A's integrated manifold, the exhaust ran cooler, which meant these hydrocarbons weren't heated enough to convert to a gaseous state, and their liquid particles clogged the DPF filter. The problem compounded itself during the DPF regeneration process, as the unburnt fuel would combust and raise temperatures high enough to damage the DPF substrate.

The fallout

To say that the pursuit of innovative technology backfired would be an understatement. Maruti Suzuki seemingly looked deep into finding a fix, even considering replacing the integrated exhaust manifold with a conventional one. In the end, the carmaker decided to abandon the project, but not before launching its Ertiga MPV with the E15A engine — barely five months before its announcement of a diesel-free future.

There were good reasons for the carmaker to abandon diesel engines. The rising cost of diesel fuel brought it closer to the price of gasoline, and the price of additional additives required for a BS6-compliant engine negated the diesel's low running cost advantage, especially when it came to smaller engines. Maruti Suzuki did well by focusing on other engines, offering multiple alternatives to gas-powered options like compressed natural gas vehicles, hybrids, and even EVs. Even so, the E15A blunder could easily stand alongside the biggest flops in automotive history, and it's one that Maruti Suzuki likely won't forget anytime soon.