Why Some Engines Have Both Port And Direct Injection

Port fuel injection (PFI) was a major milestone in the early '80s. The integration of PFI rapidly changed the way fuel was delivered by increasing fuel economy and improving engine performance. Even with advancements in fuel delivery like gasoline direct injection (GDI) on some newer vehicles, PFI continues to remain a valuable player in the way fuel is delivered today. Yet with GDI being a newer option, the question still remains — why do some engines have both port and direct injection?

The answer is far from simple, but there are key reasons why some automakers are using dual fuel injection systems: increased efficiency, increased performance the ability to meet constantly changing emissions standards.

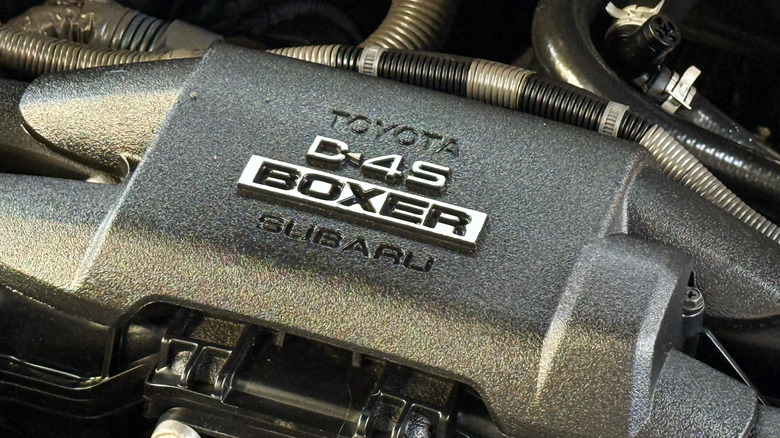

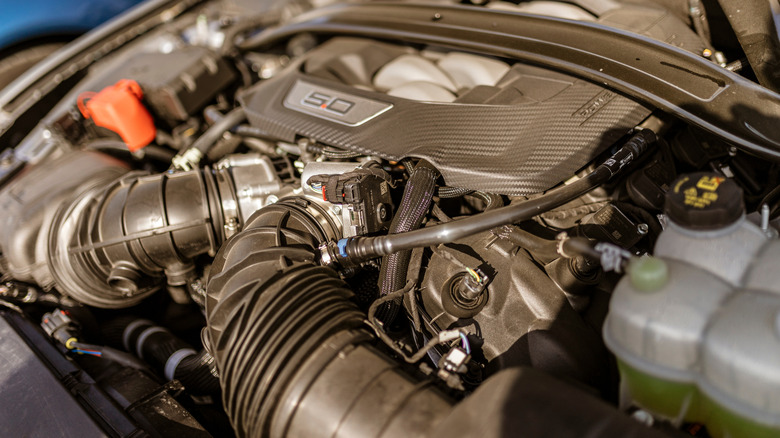

Many engines operate more efficiently using a combination of both GDI and PFI. For example, automakers like Ford, Toyota and Audi, just to name a few, all have engines which make use of a dual-fuel injection system. Some of the biggest benefits of using GDI and PFI in combination include cost effectiveness as well as smoother and quieter engine operation. Perhaps the biggest benefit? The combination of both GDI and PFI working together in harmony to cancel out each other's negatives.

The advantages and disadvantages of GDI and PFI

Let's first take a look at the differences between GDI and PFI, as each style has its own pros and cons. For starters, GDI is a fuel-delivery system designed to deliver highly pressurized fuel directly into the combustion chamber of the engine. On the other hand, PFI uses a dedicated fuel injector (or sometimes multiple injectors) for each cylinder. Fuel injectors are typically mounted on (or near) the engine's intake manifold via a fuel rail.

Some of the pros of GDI include improved fuel economy, better performance, and a cooler cylinder charge. This is achieved by the nature of how GDI works. Since fuel is injected directly into the engine's combustion chamber — and often at a more precise level — a cooling effect is created, enabling increased compression ratio. This results in a much more powerful and efficient engine. The drawbacks of GDI can be just as impactful, however. GDI engines have been known to fall victim to clogged fuel systems and even engine carbon buildup. Neither of these are cheap repairs.

One of the biggest advantages of PFI is cost. For example, the cost of a single fuel injector can be as little as $40, though this does depend on your specific vehicle. However, PFI has its cons as well, specifically in low-compression engines. When compression is lowered to prevent the potential for engine knock, the result is less than favorable efficiency and performance than modern GDI systems.

Combined Arms: GDI and PFI

Combining GDI and PFI helps close the gap for a better-performing engine. Essentially, both sets of injectors work in conjunction to provide the best possible fuel mixture, resulting in better fuel economy, decreased emissions and a more efficient engine. Where PFI falls short, GDI picks up the slack, and vice versa.

A great example of this is Ford's take on dual-fuel injection. Ford relies on PFI for a handful of low-stress operations, such as at idle and low RPM cruising. Yet when maximum fuel delivery becomes priority, such as high RPM load, the system is designed to use both GDI and PFI for max effort. Toyota also has its own dual fuel injection system, which is designed to create a cooling (and cleaning) effect on the combustion chamber and the valves themselves. However, in high RPM situations, GDI takes front and center stage for maximum efficiency.

The future of fuel injection is certainly exciting. As automakers continue investing in different fuel-injection methods, it will be interesting to see how far gasoline-powered engines can be pushed in terms of power and efficiency.