The Weirdest Engine You'll Read About Today Is The Sarich Orbital

In all fairness, Ralph Sarich is not your average Australian. As an inventor, engineer, and property investor, he's done it all, frankly, amassing a great fortune with his engineering and real-estate endeavors. Sarich's big break, however, came during the early '70s, with the re-imagination of what we know as the Wankel rotary engine that Mazda made famous.

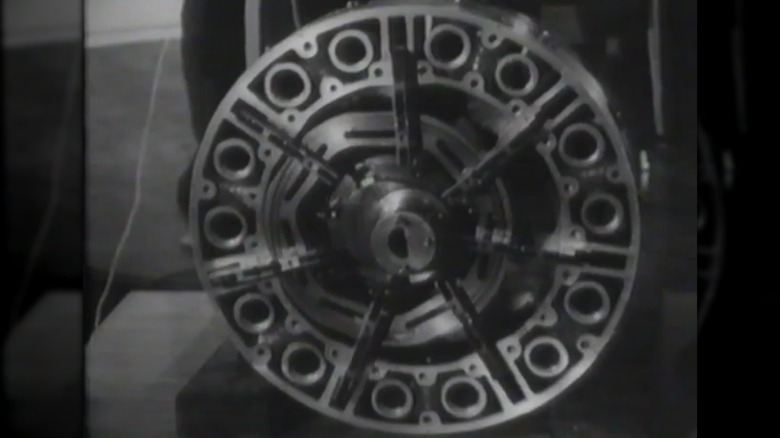

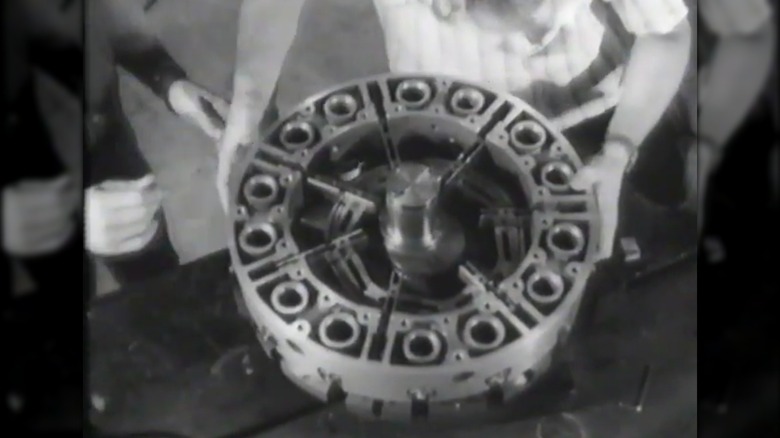

His version, dubbed the Orbital engine, had the rotor orbit around the crank/output shaft instead of rotating, which was a Wankel hallmark. It's complicated and unconventional, shall we say, so here's an archived video from 1973 to help you better visualize the engine.

The orbital design, according to Sarich, made the engine light and compact, while retaining the Wankel's desirable power and high-revving characteristics. Not only that, but the Orbital engine had much superior wear resistance, unlike the rotary with its fair share of pros and cons.

While the engine certainly brought him fame, for a brief moment at least, the design wasn't flawless, as it ran into cooling and lubrication issues. Although he claimed the Orbital had better emissions, sealing, and fuel economy, Sarich couldn't get the engine production-ready, even after nearly a decade of research and testing.

Sarich dropped the Wankel idea, but realized the fuel injection system he created for the Orbital could be adapted for use in two-stroke applications (though not the same as the two-strokes used in motorcycle racing engines). Lo and behold, the OCP (Orbital Combustion Process) engine was born, using an air-assisted direct fuel injection system, dubbed OFIS (Orbital Fuel Injection System), which allowed the engine to run an A/F ratio as lean as 31.5:1. The tech was first prototyped around the early '80s in three-cylinder two-stroke Suzuki-sourced engines.

Wankel out, two-stroke in

Although Sarich sold his stake in the Orbital Engine Company (OEC) after realizing the Wankel re-imagination was not going to work, the OCP two-stroke proved promising, as it dealt with the traditional two-stroke's poor combustion efficiency and emissions characteristics. As you may know, conventional two-stroke engines (the crankcase-scavenged kind) have a tendency to burn oil. It's part of the design, to be fair, which is why you mix lubricating oil with the fuel. Another design-related compromise (if symmetric port timing is used) is that unburnt air and fuel are often pushed out through the exhaust port, which is not good for power or emissions.

The OCP engine improves combustion efficiency by directly injecting the fuel mixture after the exhaust port closes. That meant cleaner and fuller combustion. This unlocked better knock characteristics and fewer emissions (particularly NOX), making the engine capable of meeting even the strict U.S. emissions standards of the time. However, it's worth pointing out that this was partly achieved thanks to the use of a two-way catalytic converter. Although a small oil pump was added to curb the engine's oil-burning nature, it was never fully eliminated.

Enter the 1990s, and Ford, GM, Pininfarina, and Volkswagen all showed interest, but unfortunately, nothing came to fruition. Although the OCP engine (in prototype format) was cheaper, space-efficient, offered better fuel economy, and lower emissions, it couldn't do everything at the same time. Besides, four-stroke engines were getting better, so the OCP engine was too big a gamble for the car industry to adopt. The technology, therefore, was relegated to more niche applications like certain scooters and marine outboards. You can also find it used in Orbital-developed drone engines these days.