Why Automatic Transmissions Have Flex Plates Instead Of Flywheels

Several components mediate between the output produced by your car's engine and the power that ultimately gets to the driven wheels. In a manual car, the power transfer process is helped by a clutch, which is classified as either dry or wet based on its operation. As a mechanical device, the clutch connects your car's engine to the transmission, managing the power transfer and allowing the engine to keep running while the car is sitting still.

As it is attached to the rear flange of the crankshaft, the flywheel also plays a very important role in making all of this happen. When your foot is off of the clutch pedal, the pressure plate inside the clutch assembly holds the clutch disc against the flywheel, connecting the engine to the transmission and consequently allowing power to flow through and drive the wheels. On the other hand, pressing the clutch pedal to the floor prompts the throwout bearing to bring the pressure plate away from the flywheel, severing the engine power from the transmission to allow you to come to a stop without stalling as well as change gears smoothly without grinding.

Meanwhile, flex plates are part of how automatic transmissions work. In traditional systems, the role of a clutch is performed by a torque converter, which uses a fluid coupling. While a clutch relies on a flywheel, a torque converter works together with a flex plate to direct the engine's power to the transmission in an automatic vehicle. This is due to the fluid coupling of the torque converter, as it eliminates the grinding associated with manual clutches, making a heavy metal disc such as the flywheel unnecessary.

The flex plate serves simple but crucial functions

One factor that characterizes the flex plate as as a better partner for the torque converter is its ability to flex slightly without breaking. It can do this because it's much thinner and lighter than a flywheel, which is heavy and solid. This allows it to bend forward and backward along its main axis as the crankshaft rotates faster, absorbing any minor misalignment between the engine and transmission as well as the vibrations that occur while the engine is running. Also, since fluid pressure normally fills the inside of the torque converter and causes it to expand a little, the flexible nature of the flex plate permits this expansion without causing more issues.

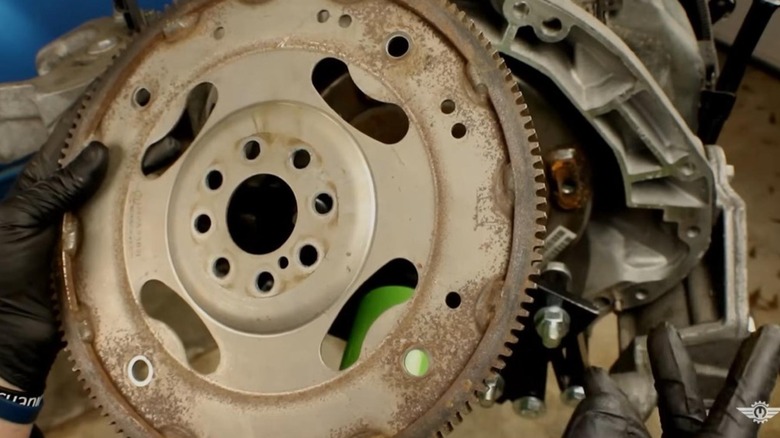

Much like a flywheel, the role of a flex plate in the drive train is pretty straightforward. With one side attached to the crankshaft, the other side bolts to the outer shell of the torque converter, allowing it to act as a direct link to the engine. As the engine rotates, its movement is passed along to the flex plate, which in turn spins the torque converter housing, prompting it to drive the hydraulic pump inside the automatic transmission.

The flex plate also features a ring gear along its outer edge that's engaged to turn the engine over during startup. When you turn the ignition key, the starter motor's pinion gear connects with the teeth of the flex plate's ring gear. This allows the starter motor to spin the flex plate, which then rotates the crankshaft to get the engine fully started. As the engine starts, the flex plate continues to play its role by transferring rotating power from the engine to the torque converter.