The Tools That Help Save Your Sanity (And Your Knuckles)

We all love working on cars, but we all know a project can end up far more frustrating than expected. We may not all get trench foot while wrenching, but plenty of us have run into stuck bolts, cramped engine bays, or endless rust that can turn a two-hour project into a two-day ordeal. Today, I'm here to deliver you from such despair, and teach you the tools that'll make your wrenching life a breeze. Or, at least, mildly less frustrating.

For me, personally, there are a few big frustrations I run into when wrenching. My automotive tastes run small and modern, which means plenty of cramped engine bays with little room to turn a wrench around any given fastener. I'm also from the Northeast, land of rusted-on bolts, so we've got some solutions for dealing with those. Finally, we have a single solution for all sorts of problems: Hard-to-find parts, oddly specific tools, and more.

Cordless ratchet

In my youth, I once owned a Jeep Wrangler with a cavernous engine bay that could fit any number of tools, lights, or small European nations between the engine block and the radiator. Since then, I've exclusively owned meticulously-engineered space-constrained Japanese and German vehicles that barely allow you room to fit a wrench, let alone turn it. From that frustration, I've found one of the most useful power tools around: The cordless ratchet.

Is a cordless ratchet stronger than a cordless impact? Almost universally not, no. Will it be useful in pulling off lug nuts? It will not. But when you barely have room to squeeze a socket wrench somewhere, the cordless ratchet will feel like a lifesaver with its ability to just spin those frustrating little fasteners. It's so, so much better than cranking a socket wrench one click at a time for what feels like days if not months on end.

Breaker bar

Sometimes, though, precision isn't the issue. Sometimes you have a big, easily-accessible bolt, and it's just rusted so firmly in place that you start to wonder if it's welded. In those situations, a cordless ratchet won't help you. Hell, a cordless impact probably won't move the needle. In situations like that, you need to turn to most old-fashioned of force multipliers: A really big stick.

That is to say, a breaker bar, so named for its ability to break loose stubborn nuts. There are purpose-built solutions for this, extending Harbor Freight handles that fold up nicely and neatly to fit in your toolbox, but sometimes there's no replacement for the good old method of putting your floor jack handle around a socket wrench and pulling with all your strength. I've managed to snap sockets doing this on some thoroughly-stuck brake caliper bolts, so it can be worth using impact sockets if you've got them. It can also be worth buying your next car from a state that doesn't salt its roads in winter.

Impact screwdrivers

What if you need precision and force? Well, then, I truly don't envy whatever job you're working on. For pulling out small screws like Phillips or flatheads that have rusted into place, you may look to something like a hand impact driver that converts the force of a hammer hit into rotation. I, however, propose something even cleaner: Impact screwdrivers.

They look like regular screwdrivers. They act like regular screwdrivers. But when something's really, truly stuck, you can hit one with a hammer and watch it turn — just enough to break the screw loose, because you really don't need more than a few degrees for this. That turn comes as the hammer is forcing the screwdriver into the screw, too, to avoid stripping. The screwdriver I linked is relatively cheap and widely available, but you may even be able to find something similar at your local hardware store.

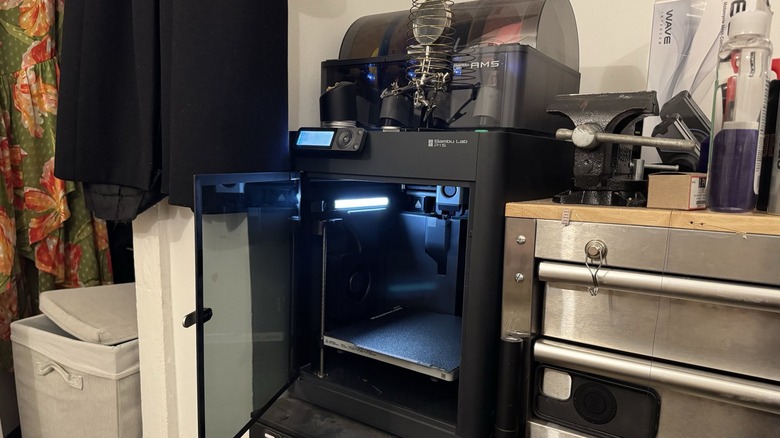

A 3D printer

Last but not least, the big one: A 3D printer. This isn't a small, cheap, or simple tool by any means, but it's amazing how many problems it solves all in one device. Just for kicks, a short list of automotive prints I've made from my own printer:

- Replacement brackets for my track-prepped Miata

- A lightweight, compact replacement center console for that Miata

- Chain measurement tools for various motorcycles, sized to the proper in-spec chain slack for the bike

- A brake reservoir wrench for my F800GS, which had the most frustrating front brake reservoir I've ever seen

- Under-seat storage on my F800GS

- Phone mounts for multiple vehicles

- Camera mounts for multiple vehicles

A 3D printer isn't just a tool for solving problems like "the manufacturer no longer makes this trim piece I need," it's a tool for solving problems like "I wish I had a wrench that bent at this weird, specific angle to reach this one exhaust bolt." Once you buy the printer, individual prints are dirt cheap — it suddenly becomes reasonable to print those weird one-off tools you wouldn't otherwise bother with. At that point, the ability to print real and functional car parts almost becomes a bonus.