Why Did Automakers Start To Use MacPherson Struts?

MacPherson struts are fairly common in modern cars, particularly in front-wheel-drive formats. So why is this specific independent suspension setup so popular? As is the case with many things engineering, automakers have their fair share of reasons to incorporate a certain design or technology. More often than not, it boils down to cost, and it's no different here. From an OEM perspective, the hardware is simple and gets the job done without breaking the bank.

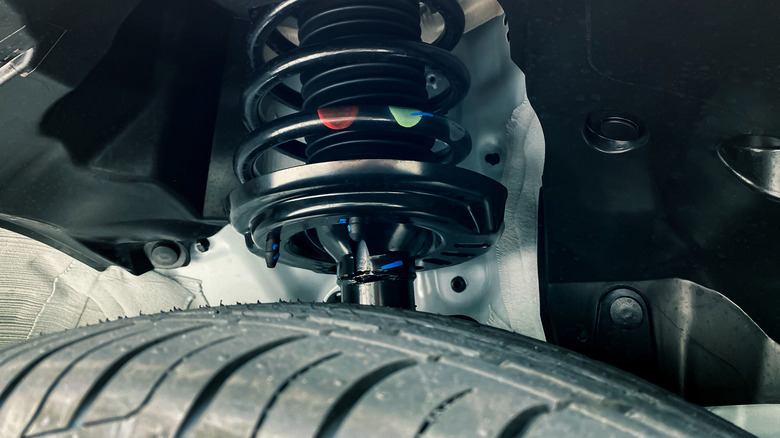

The MacPherson layout is pretty straightforward, with a steering knuckle, lower control arm, coil spring, damper, and a top mount, completing the arrangement. As far as common automotive suspensions go, the MacPherson strut is generally considered the least complicated – it's a basic triangular design, forming a three-point fixing structure between the wheel and chassis.

Modern MacPherson layouts have progressed quite far from the initial design, but their ethos is pretty close to the original, making the technology common among many designs you see on the street today. Let's look at how MacPherson struts came to be and what advantages they offer in modern suspension systems.

A bit of history

The story of the MacPherson strut begins with Earle S. MacPherson, an immensely talented engineer and the brains behind the technology, who pioneered the concept during his time at General Motors. MacPherson was the chief engineer responsible for developing the Chevrolet Cadet, a small but influential Chevy project that brought along several notable innovations including this now-famous suspension design. The prototype vehicle was touted as a revolution in automotive engineering, especially for the mid-1940s.

However, the bean counters at GM canned the project so the disgruntled MacPherson went to Ford, where he was finally able to bring the technology to a production car. The groundbreaking hardware saw its introduction in the 1951 Ford Consul and the 1951 Zephyr, cars that weren't quite as popular in the U.S. as they were in the U.K. Although they were also available stateside, sales were pretty poor, topping out at around 4,000 units sold per year domestically.

Why automakers choose a MacPherson strut suspension

Despite the slow start, MacPherson's engineering solution offered several advantages that automakers soon recognized. Chief among these was its overall simplicity, which meant that it had fewer failure points than similar systems.

For instance, there's no upper control arm in a MacPherson strut. Not only does this unlock more space, but it also reduces the vehicle's overall weight, aiding in better efficiency and ride quality. The softer ride comes courtesy of the longer coil springs, which are made possible by the strut's naturally elongated design. Additionally, the design allows the suspension loads to be absorbed by the body shell rather than the arms themselves, so the lower wishbone can be made lighter.

The MacPherson strut's simplicity, packaging perks, and lighter weight contribute to its popularity among most automakers. But perhaps the biggest reason is cost. Fewer parts mean less money to spend per unit, making it a cheaper alternative to more complex solutions like multi-links and double wishbone arrangements. And it's not like there is a lot of sacrifice. Yes, there are compromises like the reduced camber adjustability and less room for wider tires, but they are much easier to stomach when you're looking to save money. For carmakers, cost saving is an important metric, and as far as suspension designs are concerned, the MacPherson strut often makes the most economic sense.